Metal Ore Processing

After mining, crushing, mineral processing and refining, metal can be extracted, and these metals are processed into various products, widely used in construction, machinery manufacturing, electronics, transportation, aerospace and other industries.

Application direction of metal ore

Metal ores are ores that contain metallic elements or their compounds and are primarily used to extract metals. According to the different metals contained, metal ores can be subdivided into the following categories: 1. Precious metal ores: such as gold, silver, platinum group metal ores, etc., mainly used in jewelry, currency reserves and some high-tech products manufacturing. 2. Non-ferrous ores: including copper ore, lead ore, zinc ore, aluminum ore, etc., widely used in wire and cable, building materials, automobile manufacturing, aircraft manufacturing, electronic products and other fields. 3. Ferrous metal ores: such as iron ore, manganese ore, chromium ore, mainly used in steel production and other alloy manufacturing. 4. Rare metal ores: such as tantalum, niobium, lithium, etc., are crucial to high-tech industries such as electronics, aerospace, and new energy vehicles. 5. Radioactive ores: such as uranium ore and thorium ore, mainly used in nuclear power generation and medical fields.

-

Jewelry

-

Electronic products

-

Building materials

-

Automobile manufacturing

-

Aerospace

-

Medical fields

Metal Ore Processing technology

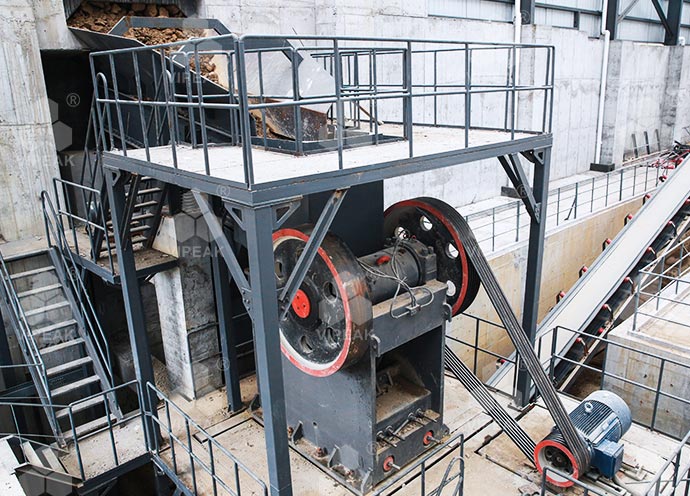

Crushing and grinding operations are two important links in the whole beneficiation process, and

they are also two

operations with huge investment and high energy consumption. As far as metal mines are concerned,

the equipment

investment in grinding operations accounts for about 65% to 70% of the total investment in the whole

plant, and the

electricity consumption is about 50% to 65%. Therefore, following the scientific principle of

grinding technology,

improving the grinding process, more grinding and less grinding is an effective way to achieve low

consumption and

increase economic benefits.

The crushing system is the core system of the entire metal ore production line. As the key equipment

of the crushing

system, the crusher plays an extremely important role in the product quality and stable operation of

the entire

production line. Vipeak will use more than 30 years of deep mining industry experience

wholeheartedly to provide you

with systematic classification production, a variety of crusher combinations and other metal mine

crushing solutions.

-

Iron Ore

Iron Ore

-

Gold Ore

Gold Ore

-

Copper Ore

Copper Ore

-

Lithium Ore

Lithium Ore

-

Manganese Ore

Manganese Ore

-

Chrome Ore

Chrome Ore

-

Nickel Ore

Nickel Ore

-

Aluminum Ore

Aluminum Ore

-

Magnesium Ore

Magnesium Ore

-

Lead zinc Ore

Lead zinc Ore

-

Chromite

Chromite

-

Magnetite

Magnetite

More related equipment

-

-

More related equipment about construction aggregate