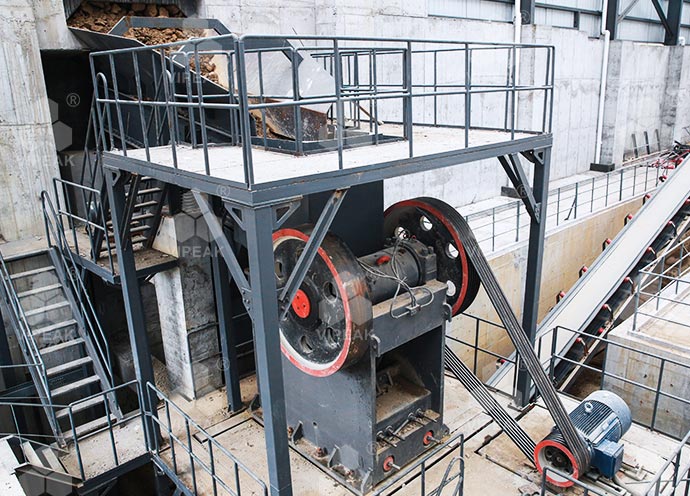

Photo Album

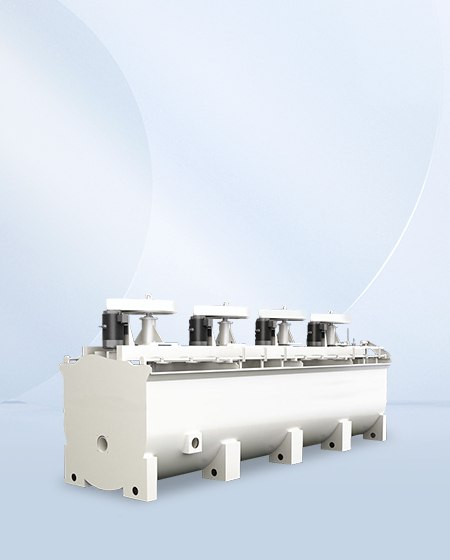

Working Principle

F5X Series Vibrating Feeder’s dual eccentric shaft exciter generates excitation force. A gear pair-connects the two eccentric shafts, enables the shafts rotate to opposite direction with same speed. Through motor driving, the excitation force generated constantly, the material slides and bounces ahead to crusher on the feeder groove. When material go through the feeder’s grid bars, the smaller material will fall down through the gap between grid bars and be sent to next crushing process. It enables the feeder to pre-screen material and fully ensures the crushing plant’s high crushing efficiency and capability.

Performance

Super-Heavy Chute Body Able to Hold High Pressure and Strong Shocks

Different from the light chute of traditional feeders which use 16# or 20# joist steel and box iron as the longitudinal beam, the super-heavy chute F5X Vibrating Feeder adopts large rectangular tube, able to hold high cabin pressure and strong shocks from falling materials and able to feed materials continuously.

Strong Vibration Intensity, Large Operation Capacity

Vibration intensity G-force is the key index to measure vibration machine's performance. The stronger it is, the larger operation capacity is. F5X Vibrating Feeder benchmarks international leading technologies and adopts advanced design philosophy and manufacturing technique. The vibration intensity is up to 4.5G, which is 30% larger than traditional devices. In the same specification, it has more operation capacity.

Efficient, Reliable & Convenient FV Super Vibrator

To satisfy higher performance and heavy load, repeated start-stop, frequency change and other poor conditions, F5X Vibrating Feeder is equipped with FV super vibrator just like a heart, which achieves reliable operation, convenient maintenance, interchange of components and high degree of commonality. The lubricating maintenance period is up to 1500 hours.

Reasonable Arrangement of Rods, Efficient Pre-screening Function

The rods are made of NM wear-resistant steel material which has long life expectancy and high screening efficiency. The installation is quite easy, too. The ladder structure formed by two sets of rods can screen out part of fine materials, so the load of primary crusher is reduced greatly.

Digitized Machining, Higher Precision

Vipeak has dozens of CNC (Computer numerical control) machine production lines. From steel plates' cutting, bending, planning to final painting, all steps can be controlled numerically. High processing precision assures that key parts have higher standards.

Specifications - Technical Data

Related Cases

-

Malaysia Stone & Sand Production Site

-

Guizhou Copper Ore Crushing Line Project

-

Iron Ore Crushing Plant Solution Design