Inner Mongolia a magnetite crushing and screening production line is in smooth production. This project is built by our company as a demonstration project as this benchmark enterprises. The customer procured our core equipment for this key project, which wa a repeat order.

Raw material:magnetite

Feed size:0-800mm

Discharge particle size:0-5 and 5-25mm

Design output:700T/H

Processing method:dry

Finished product application:Iron and steel processing plant

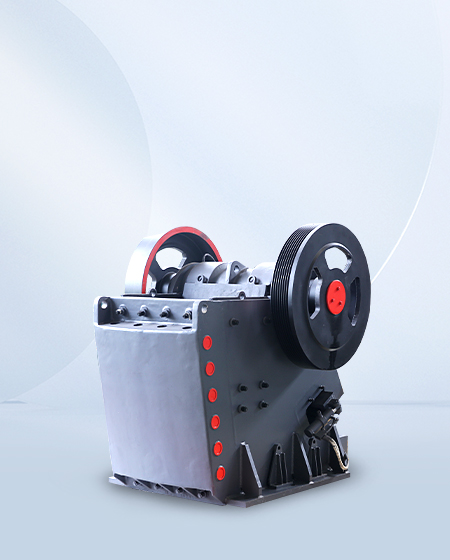

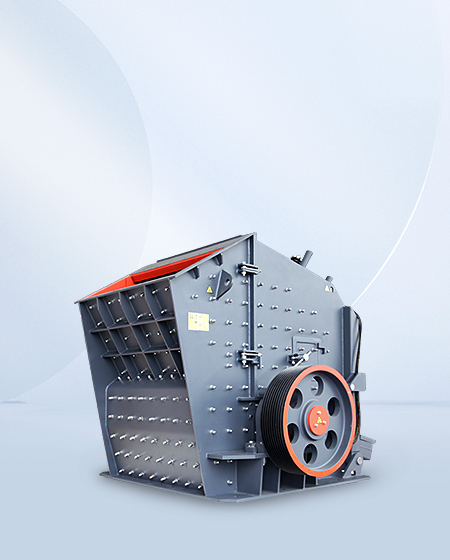

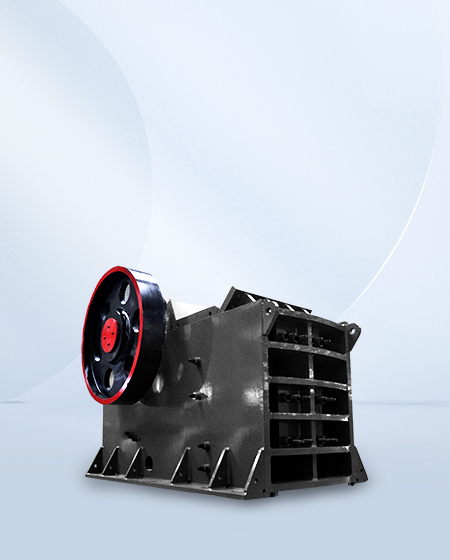

Main Equipment:One set of grizzly feeder F5X1660, one set of C5X1450*1100 jaw crusher, one set of HST315S single-cylinder hydraulic cone crusher, two sets of HPT500 hydraulic cone crushers, three sets of S5X3075 vibrating screen, supplemented by suitable feeders, with finished product size range 0-5mm and 5-25mm.

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

The material processed in this project is magnetite, the grade of magnetite is not high, according to the characteristics of the material and the output demand of the customer, we designed a 700tph crushing and screening production line. At the beginning of the project, our technical team made many field research visits to fully meet the customer's needs before forming process flowchart, so that our main equipment matched well with the existing equipment on site, reducing investment costs and increasing profit margin.

The project adopts high-quality, low-cost, high-efficiency and low-energy-consumption equipment, and the production line is constructed with the mine development concepts of ‘low-carbonisation’, ‘digitalisation’ and ‘intelligentisation’. The production is stable and efficient, which ensures the established ecological benefits and achieves further increase in production and efficiency.