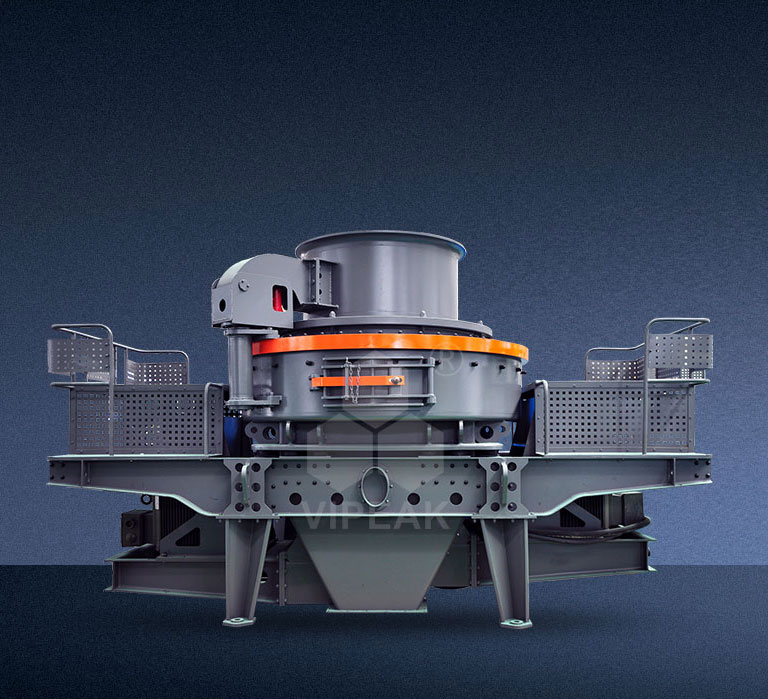

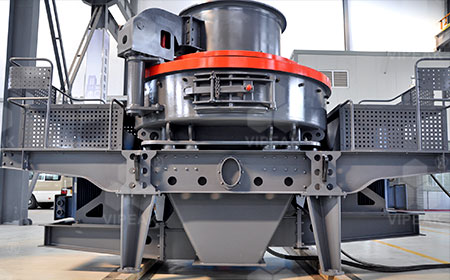

Photo Album

Prouduct Composition

Performance

Optimized Impeller Enhances Efficiency By 30% And Reduces Wear By 40%

Through systematic mechanical analysis and verification, vipeak optimized the structures of impeller and vulnerable parts. Compared with the traditional sand makers, VSI5X Sand Maker obviously increases the material throughput and ratio of crushing, and enhances the working efficiency by 30%-60%. The wear costs of vulnerable parts reduce by more than 40%.

Hydraulic Device to Open the Cover Automatically Reduces Maintenance Costs

In consideration of the maintenance and part replacement during the production of the sand maker, vipeak introduced semi-automatic hydraulic system. By only pressing a button, users can open the top cover of the machine to carry out following operations. So, this system greatly saves labor costs and enhances the service efficiency.

Split-Type Structure, Extended Service Life of Spare Parts

Based on the actual situations of production, we found that some spare parts like the periphery guard board and impact block always wear terribly at some specific points. So, to avoid this phenomenon, vipeak adopts the split-type structure when designing quick-wear parts, which not only greatly extends service life of quick-wear parts, but also reduces their using costs a lot.

Brand New Feed Mode

In consideration that customers may have two production demands (i.e. sand making and shaping) which require the switch between central feeding and fall feeding, VIPEAK made a brand new improved design on the material distributing tray so that users can easily switch the feed mode, shortening downtime for adjustments.

Specifications - Technical Data

Related Cases

-

1500TPH Crushing and Sand Making Plant in Lo···

-

Gansu Lanzhou 400TPH Tuff Project

-

Chongqing Nanchuan 1000TPH limestone Project