Photo Album

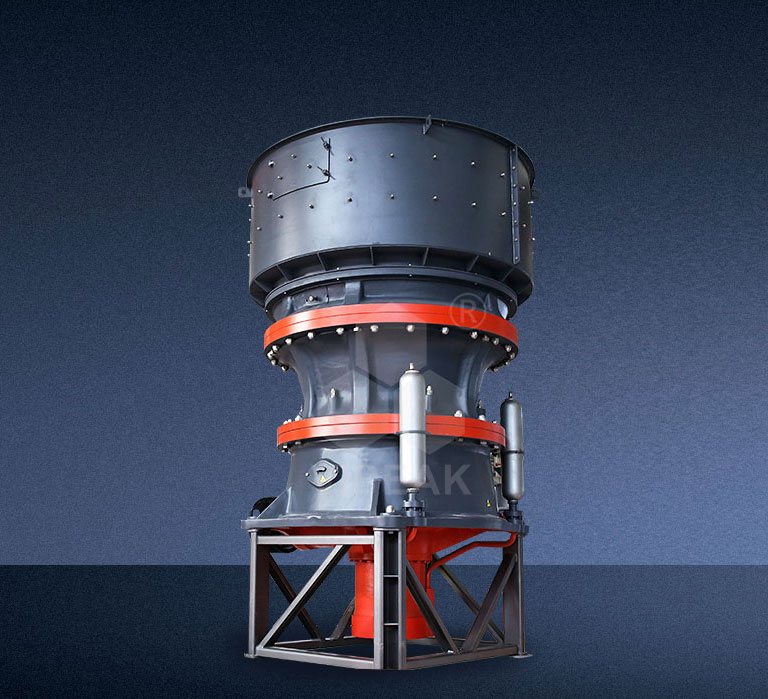

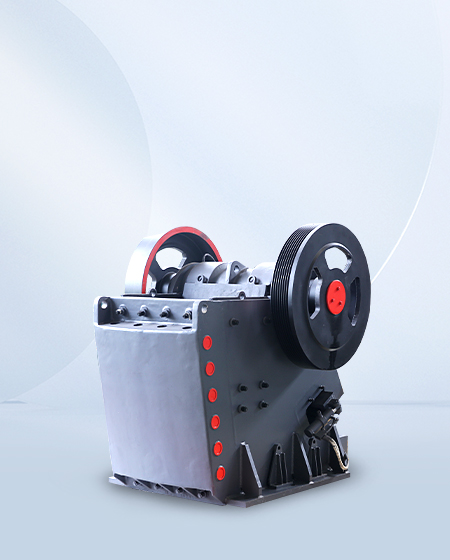

Working Principle

The electromotor leads the eccentric sleeve to rotate by the V-belt, drive shaft and drive gear. The movable cone does rotary and pendulum movement under the leading role of eccentric sleeve which makes the movable cone and fixed cone close and far away from time to time. The raw material is crushed in the crusher chamber by squeezing and striking continuously. The crushed stone discharges from the bottom.

Performance

High Production Efficiency, Strong Holding Capacity

HST Single-cylinder Hydraulic Cone Crusher achieves higher production efficiency and better product quality by matching suitable crushing cavity, eccentric distance and movement parameters. Combined with optimized strength and high-quality components, HST Hydraulic Cone Crusher has bigger holding capacity and crushing ratio as well as stronger throughput capability.

Fully Automatic Control Covering Whole Production Process

The fully automatic control system equipped on the HST Cone Crusher can provide manual control, constant discharge opening control, constant power control and many other operation modes for users to select. It can continuously monitor the internal actual load of the crusher to optimize the use ratio of the crusher and allow it to play its best performance at all times.

Easier for Maintenance, More Effective for Cost Savings

HST Hydraulic Cone Crusher has a simple structure. Almost all checks and maintenances can be done by only taking down the upper rack. The structure can not only make maintenances and checks get easier, but also save maintenance costs a lot. Besides, HST Single-cylinder Hydraulic Cone Crusher is compact on its structure, occupying small floor area, which further cuts expenditures on the foundation building.

Multiple Cavity Types Meet Various Production Needs

HST Hydraulic Cone Crusher has several kinds of standard crushing cavities which can fully meet the secondary, tertiary and even quaternary crushing needs after primary coarse crushing.

Digitalized Processing, Higher Precision

There are tens of lines of numerical controlling machine tools. Operations such as steel plates' cutting, bending, planing, milling and paint spraying are all controlled numerically. The machining precision is high, especially for the core parts.

Sufficient Supply of Spare Parts, Worry-free Operation

Vipeak, whose businesses cover production and sales, takes responsibility for every machine produced by ourselves. We can offer customers technical services about products and original spare parts to ensure the worry-free operation.

Specifications - Technical Data

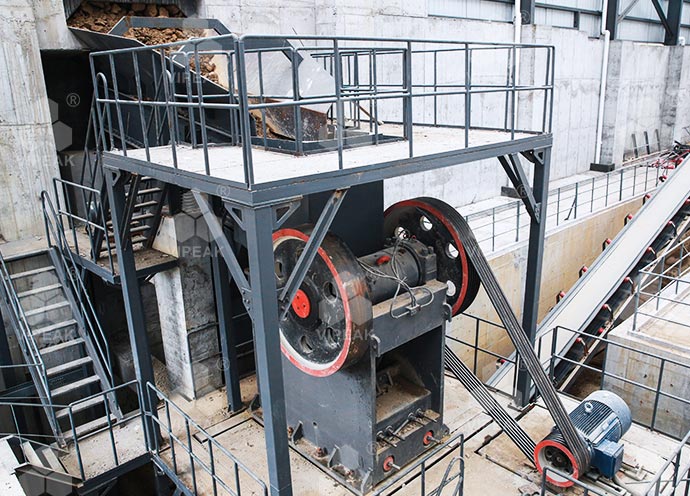

Related Cases

-

Malaysia Stone & Sand Production Site

-

Guizhou Copper Ore Crushing Line Project

-

Iron Ore Crushing Plant Solution Design