Photo Album

Working Principle

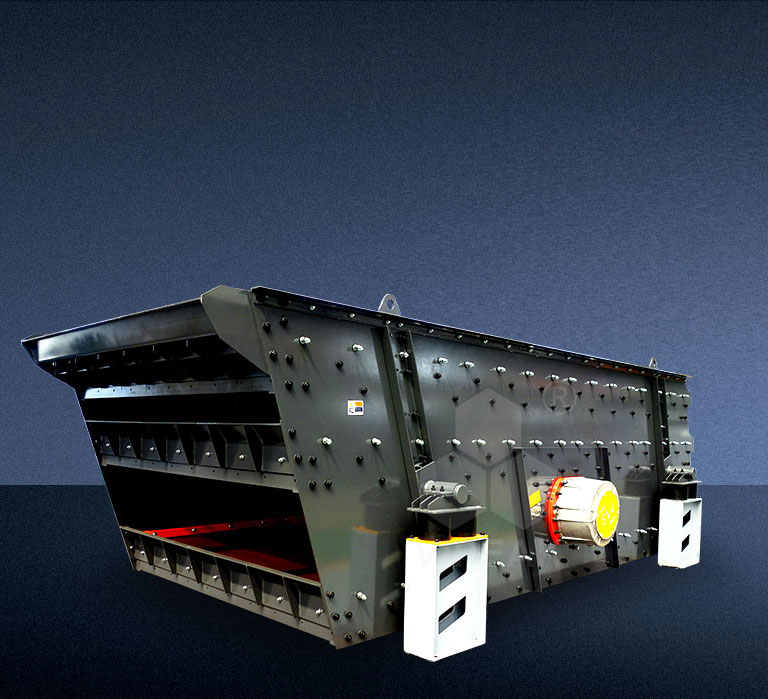

S5X Vibrating Screen adopts rubber springs as elastic supporting components and the SV super vibrator as the source of vibration. The excitation force, generated under the rotation of the eccentric block, makes the screen box do reciprocating motions. When the vibrating screen is running, materials continuously bounce and roll over on the inclined screen surface. By repeatedly comparing with the screen holes, materials smaller than the screen size would be sieved out while larger ones retain on the screen surface. This is the whole screening process.

Performance

Stronger Vibration Exciter Improving Screening Efficiency

S5X Vibrating Screen adopts the SV super-energy vibration exciter. The vibrating strength can reach the international advanced level. Further, the throughput, screening efficiency and capacity can get improved greatly. What matters is that users can adjust the vibration amplitude quickly by adding or reducing standard weight balancing blocks of the vibration exciter.

Optimized Screen Box Structure Making Operations More Reliable

The screen box of S5X Vibrating Screen adopts the FEM simulation analysis, which allows the ideal stress state of the side plate. There is no welded point on the side plate, so it is free from risks of fracture. All connections among structural components of the screen box adopt torsional shear bolts which has stronger strength than the ring-grooved lock bolts.

Modular Design, Lower Maintenance Costs

The vibration exciter and the screen box frame of S5X Vibrating Screen use modular structures. If there is a need for replacement, the modular vibration exciter can be taken down from the screen box to be disassembled quickly. The vibration exciter adopts special labyrinth seal design and grease lubrication which ensure its stable operation. Besides, spare parts have higher degree of general utilization. So, it is easier and quicker for later replacement of spare parts.

Optimized Transmission Manner, More Stable Operation

S5X Vibrating Screen adopts flexible drive device, which can protect the motor from strong shock and free the torque transmission from the axial force, so that the operation of the equipment is more stable. The screen is supported by rubber springs which have long service life and strong corrosion resistance, bringing smooth operation, low noise and less impact on the foundation.

Specifications - Technical Data

Related Cases

-

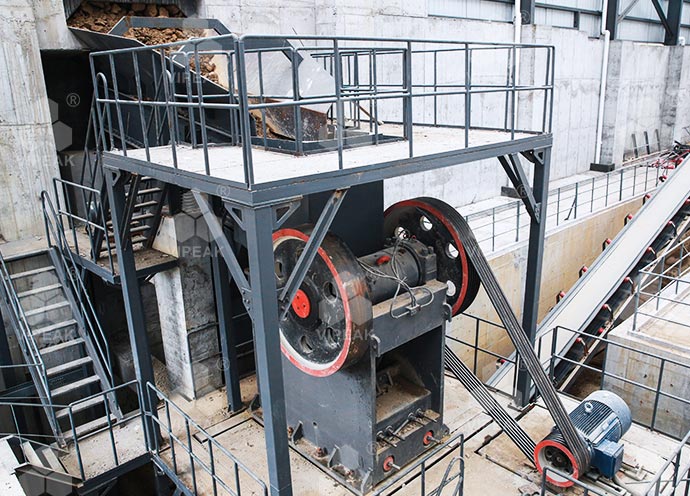

Malaysia Stone & Sand Production Site

-

Guizhou Copper Ore Crushing Line Project

-

Iron Ore Crushing Plant Solution Design