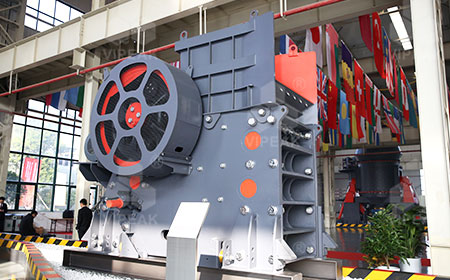

Photo Album

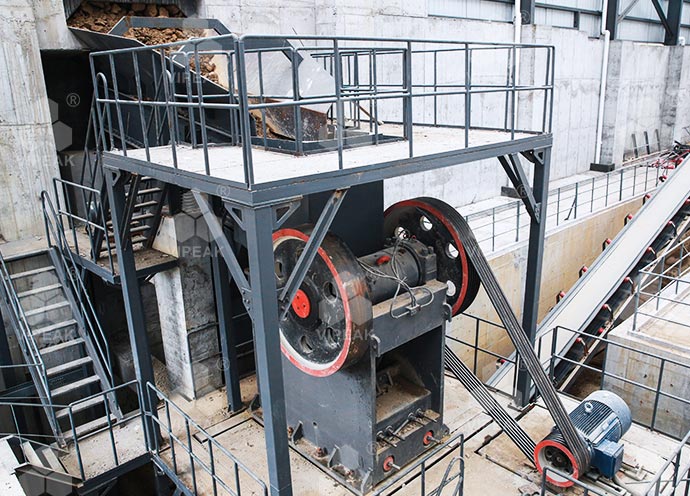

Working Principle

Input dynamic by motor, the pulley drives eccentric shaft to make the movable jaw move upwards and downwards with SPC belt. When the movable jaw moves forth toward the fixed jaw, materials in the crushing cavity will be squashed or chopped. And then the movable jaw travels back, the chopped or squashed materials which met the requirements will be discharged from the outlet. Since the motor keeps working, the crusher will crush and discharge periodically to achieve mass production.

Performance

Lean Design For Higher Quality Only

C6X Jaw Crusher boasts more reasonable moment of inertia and greater crushing strokes through optimization of the equipment structure, crushing cavity and movable jaw's motion trail and speed. It is able to achieve higher crushing efficiency at the same power consumption and thus offer customers a larger rate of return on investment.

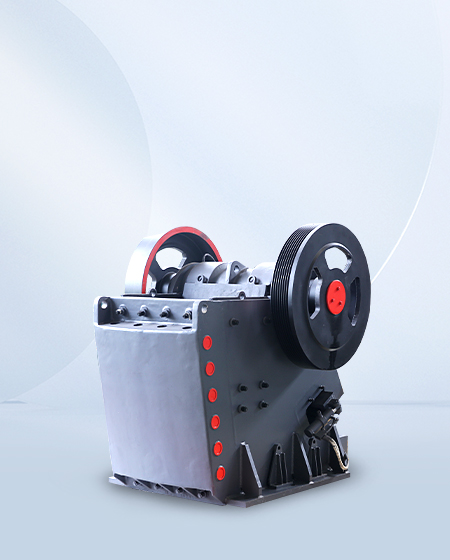

High-quality Casting Ensures Reliable Performances

In order to ensure stable and efficient production during crushing hard materials, C6X Jaw Crusher is equipped with such core rotating components as high-quality casting movable jaw body, large-eccentric heavy-duty forged eccentric shaft, cast flywheel with a high moment of inertia and high-strength integrated cast steel bearing box, as well as strong power with reasonable speed configurations.

International Top Configurations

High-quality raw materials and reliable design can provide sufficient equipment strength and remarkable durability of C6X Jaw Crusher during super-hard material crushing and thus reduce the maintenance costs.

Easy Maintenance

The C6X Jaw Crusher adopts centralized grease lubrication. Manual or automatic grease lubrication system can be configured as needed, which can reduce the difficulty in maintenance and simultaneously guarantee cleanness and neatness at the work site.

The C6X Jaw Crusher uses a double-wedge regulating discharge port with the mechanical or hydraulic regulation available as needed, so it can be regulated more simply and efficiently than the traditional underboarding discharge ports.Digitalized Processing, Higher Precision

There are tens of lines of numerical controlling machine tools. Operations such as steel plates' cutting, bending, planing, milling and paint spraying are all controlled numerically. The machining precision is high, especially for the core parts.

Sufficient Supply of Spare Parts, Worry-free Operation

Specifications - Technical Data

Related Cases

-

Malaysia Stone & Sand Production Site

-

Guizhou Copper Ore Crushing Line Project

-

Iron Ore Crushing Plant Solution Design