The project mainly uses tailings of granite to make sand. There is a subsidy by processing those tailings because it belongs to the solid waste recycling project strongly supported by the government. The completion of the production line not only solves the problem of stacking of tailings, but also creates considerable profits for the company.Its social and economic benefits are relatively high.

The project mainly uses tailings of granite to make sand. There is a subsidy by processing those tailings because it belongs to the solid waste recycling project strongly supported by the government. The completion of the production line not only solves the problem of stacking of tailings, but also creates considerable profits for the company. Its social and economic benefits are relatively high.

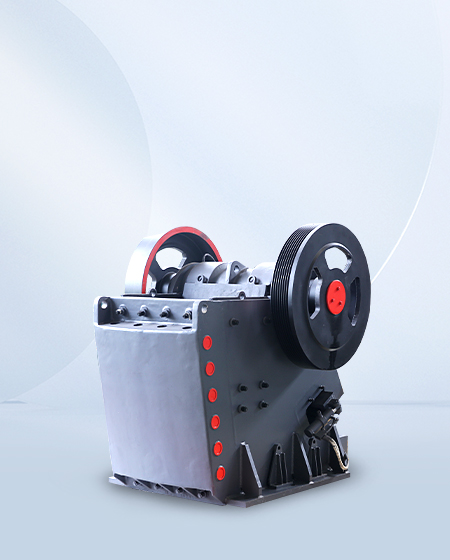

Input size:10-850mm

Output size:0-375mm

Capacity:0-760tph

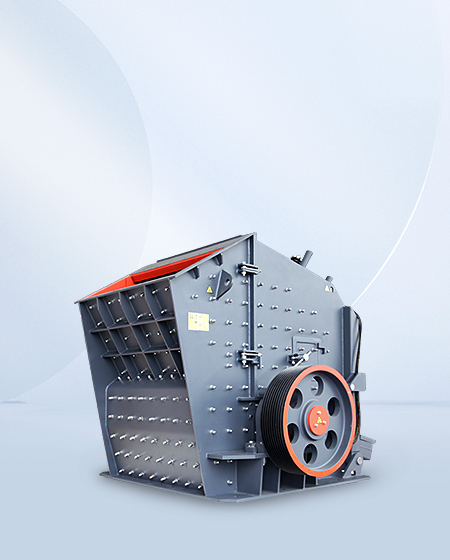

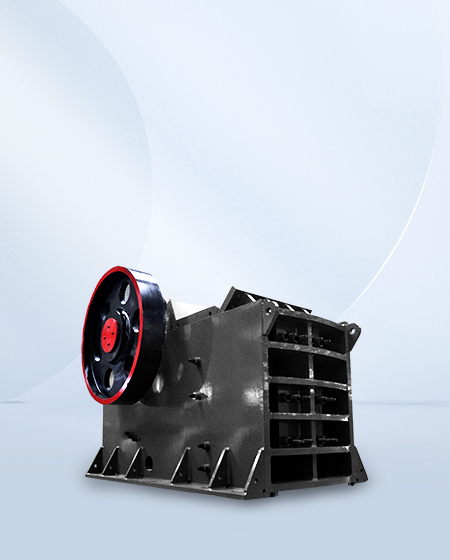

Application field:Aggregate and metal ore crushing

Applicable materials:Pebbles, limestone, dolomite, granite,

rhyolite, diabase, basalt, black and non-ferrous metal ores, etc.

Output SizeM Medium

Equipment:C6X Series Jaw crusher

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

By fully optimizing design schemes, SBM uses original tailing yard, which not only saves floor area but also reduces total investment costs.

This project adopts advanced and mature technologies and reliable equipment, ensuring efficient and stable operation of the whole production line.

Compact layout not only saves floor area, but also makes checks and maintenances easy. In this way,economic losses incurred by inconvenient maintenances can be avoided.

Screens are placed in parallel while finished products are transported by same belt conveyor.The customer can adjust the proportion of output materials according to market situations. This output can reach expected economic and social benefits.

All equipment works under fully closed environment and special dust remove devices are installed, totally meeting national standard on environment protection and effectively integrating economic profits and environmental benefits.

Since the production line was put into operation, the overall performance has been relatively stable. In terms of equipment, key equipment etc have good performance and can continuously and effectively complete the iron ore crushing task, ensuring the continuity of production. In terms of production efficiency, the expected goal has been achieved, and the crushed iron ore can be output on time and in quantity, meeting the needs of subsequent processes.