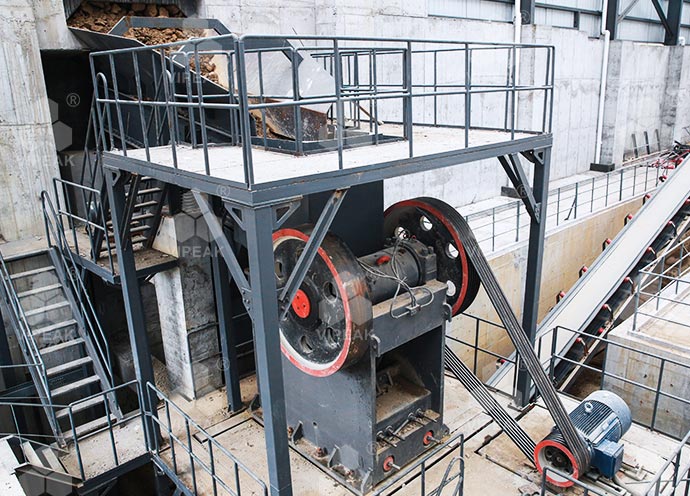

Photo Album

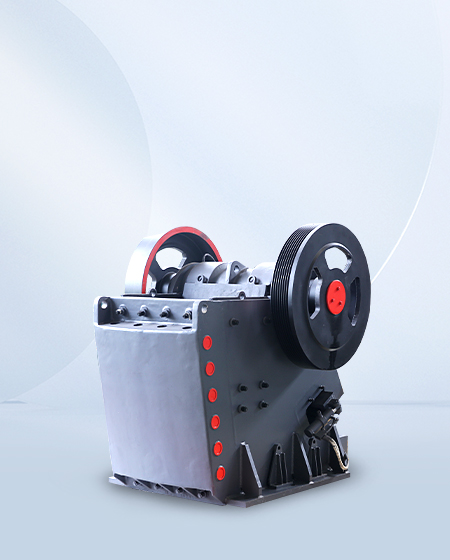

Working Principle

HGT Hydraulic Gyratory Crusher consists of beam, upper frame, middle frame, lower frame, moving cone, eccentric sleeve, transmission part and hydraulic cylinder part. Horizontal shaft driven by motor rotates constantly. Then horizontal axis makes eccentric sleeve rotate by gear, after that eccentric sleeve will drive the moving cone to swing circularly, so as to realize crushing process.

Performance

Intelligent operation and convenient control

Automation control system can used to record production information and crusher status, and it can also control every link including lubrication system. In addition, the equipment can check for faults automatically, which makes problems solved timely, downtime reduced and maintenance costs decreased.

Reliable quality and long service life

High strength frame and high performance bearings are adopted to ensure product quality and prolong service life from the perspective of raw materials. In addition, there is a positive pressure blower equipped on the dust-proof seal device, which prevents dust from entering the eccentric device and driving device, so that the service life of crusher bearing can be longer.

Large capacity and low cost

There is bigger obliquity of crushing chamber and longer crushing face and stronger, which makes crushing capacity improved. Besides, the super beam design is adopted to increase inlet size and crushing efficiency. The ore outlet control system adopts hydraulic adjustment method to compensate for wear liner and reduce maintenance cost.

Flexible adjustment and convenient maintenance

Adjusting the eccentric sleeve can change processing capacity of gyratory crusher easily. At the same time, relying on automatic lubrication system and automatic main shaft position control system, the maintenance is more convenient.

Specifications - Technical Data

Related Cases

-

Malaysia Stone & Sand Production Site

-

Guizhou Copper Ore Crushing Line Project

-

Iron Ore Crushing Plant Solution Design