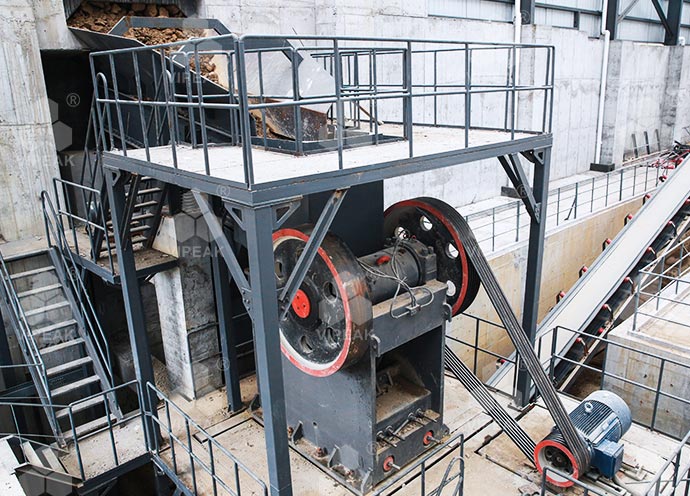

Photo Album

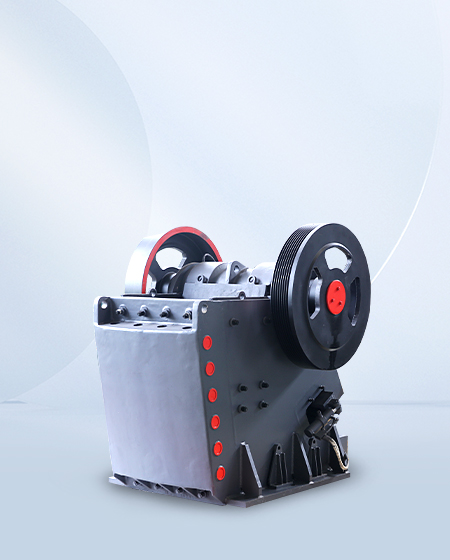

Working Principle

Under the leading role of eccentric sleeve, the movable cone of the HPT Series high-efficiency hydraulic cone crusher does rotary and pendulum movement which drives the broken walls squeeze and twist the raw material between the rolling ace tabular wall and it. According to laminated theory, the raw material is crushed and polished following their own texture by the force from different directions. Stable aggregate are produced finally. The eligible raw material falls down from the gap of the broken wall. The others will be kept crushing until it reaches the desired size.

Performance

Upgraded Structure, Higher Efficiency

Reserving unique structures like the fixed axis and the characteristic that eccentric sleeve rotates around the axis, HPT Hydraulic Cone Crusher further optimizes the transmission parts and lubrication and sealing structures. So, this crusher boasts strong holding capacity, bigger installed power, higher efficiency yet lower noises.

The Principle of Lamination Crushing Brings Better Discharging Size

HPT Hydraulic Cone Crusher adopts the principle of lamination crushing. Not only can the crushing efficiency improve, but also the abrasion of vulnerable parts reduces greatly. The finished products are cubic. Meanwhile, the content of qualified fine particles is high enough. Finished products can better serve as high-quality aggregates.

Multiple Cavity Types Meet Various Production Needs

HPT Hydraulic Cone Crusher has several kinds of cavities suitable for medium-fine or fine crushing of materials. Users can freely make choices among different cavities by changing only a few spare parts like the lining plate, truly achieving that a crusher serves multiple purposes.

Digitalized Processing, Higher Precision

There are tens of lines of numerical controlling machine tools. Operations such as steel plates' cutting, bending, planing, milling and paint spraying are all controlled numerically. The machining precision is high, especially for the core parts.

Specifications - Technical Data

Related Cases

-

Malaysia Stone & Sand Production Site

-

Guizhou Copper Ore Crushing Line Project

-

Iron Ore Crushing Plant Solution Design