This is a expansion project of a Sichuan mining company to process iron ore and it was built in 2019, which belongs to the second phase of the new project to increase efficiency and increase production, the core equipment of the project to choose to use the high efficiency and stability of the automation degree of the high degree of hydraulic cone crusher, to ensure that the production capacity of the stability of the production line to run smoothly for the customer to establish a new point of profitability and growth.

Raw Material:Iron Ore

Capacity:450T/H

Discharge size:0-25mm

Application:Preparing materials for ball mill grinding and ore dressing workshops.

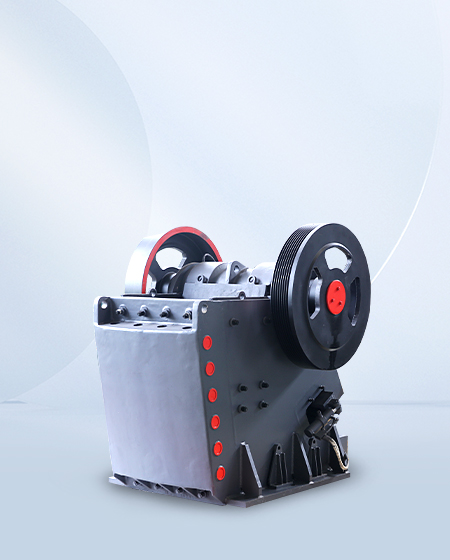

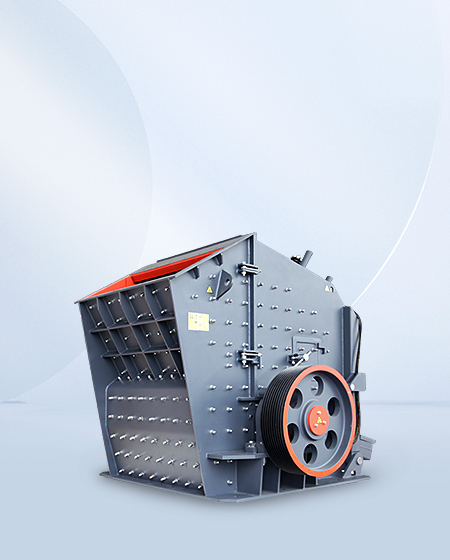

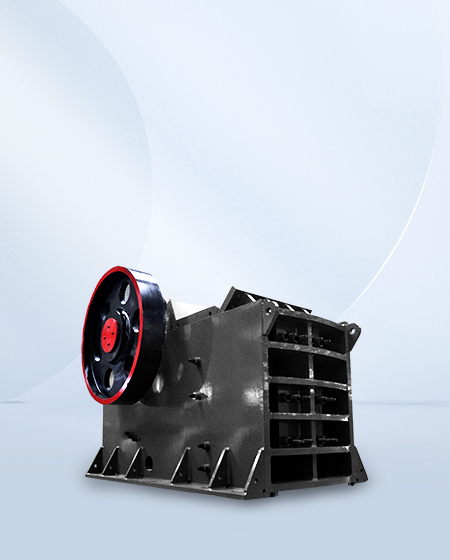

Equipment Configuration:One set of feeder F5X1360, one set of PE1000×1200 jaw crusher, one set of HST250S (coarse cavity) single-cylinder hydraulic cone crusher, two sets of HST250H (fine cavity) single-cylinder hydraulic cone crusher, and two sets of S5X3075-3T heavy-duty vibrating screens.

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

PE1000×1200 jaw crusher

HST250S (S coarse cavity type) single-cylinder hydraulic cone crusher

two HST250H (H fine cavity type) single-cylinder hydraulic cone crusher

two S5X3075-3T heavy-duty vibrating screens

one coarse crushing + two ‘crushing + screening’ closed-circuit system, multi-crushing and multi-screening, high equipment utilisation and stable production capacity.

Since the project was built and put into production, the equipment has been running well, won the praise of customers, and escorted the customer enterprises to increase production and efficiency.