A new magnetite crushing and screening production line was built by a large mining company in Sichuan, China

Raw material for processing:magnetite

Feed size:0-800mm

Discharge particle size:0-5-25mm

Designed output:700T/H

Processing:Dry

Finished product use:steel processing plant project.

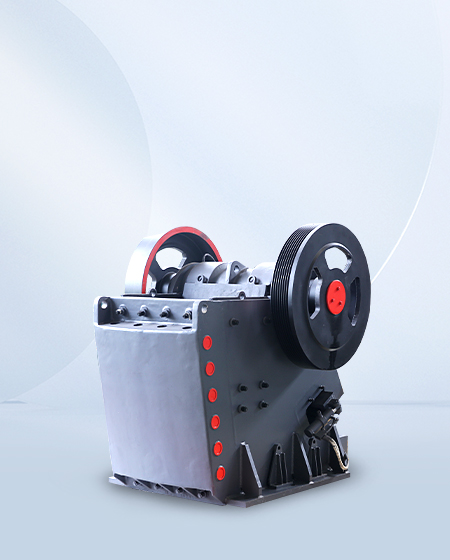

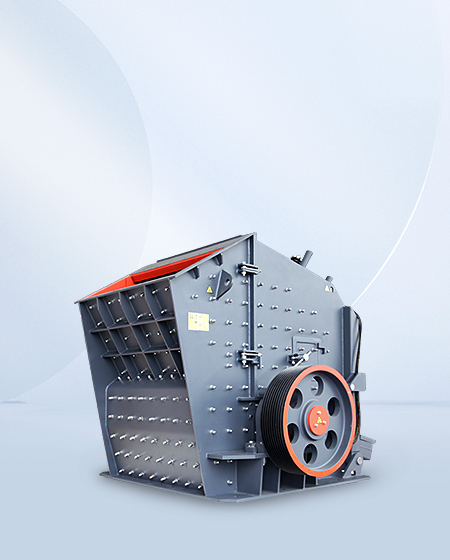

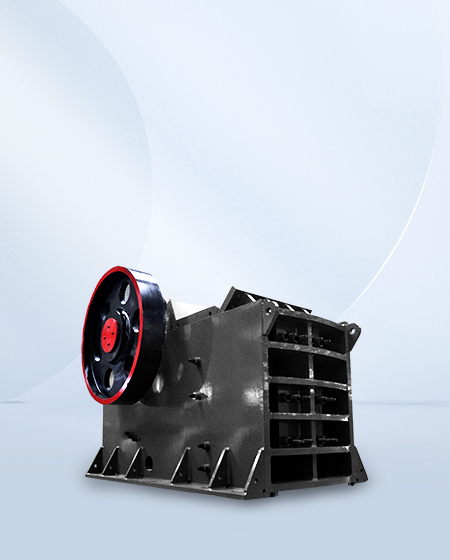

Main equipment:Feeder F5X1660 / 1 set,C5X1450*1100 jaw crusher / 1 set,HST315S single-cylinder hydraulic cone crusher / 1 set,HPT500 hydraulic cone crusher / 1 set,S5X3075 vibrating screens / 1 set

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

one coarse crushing + two "crushing + screening" closed-circuit systems.

The material processed in this project is magnetite, the grade of magnetite is not big, according to the material characteristics and the customer's output demand, our company plans and designs a crushing and screening production line with an hourly output of 700 tons for the customer. At the beginning of the project construction, our professional service team made many in-depth field research visits to fully meet the customer's needs when formulating the material processing program, so that the company's high-performance host and the customer's own equipment cleverly adapted to reduce the amount of investment at the same time, expanding the profit space.

The project adopts our company's "automation, high efficiency, low energy consumption" mature products and equipment, production line construction layout is reasonable, equipment production is stable and reliable, to ensure that the customer's established production goals beyond the expected realization.