This 1,000 tonnes of magnetite crushing production line is owned by Baotou Mining Deyuan Mining, the customer visited a number of manufacturers to compare the selection, and ultimately in our engineers and the advantages of the core technology, and the customer chose a complete set of crushing and screening production line from Vipeak. With the discontinuous operation of the mine blasting and mining taken into consideration, the customer chose two sets of coarse crushing of the production, with a capacity more than 1,400 tonnes per hour. Large buffer stockpile were set to meet the subsequent discontinuous contact with the operation of the production line. The medium and fine crushing workshop equipment mainly adopts our company's core equipment,hydraulic cone crusher, to ensure the stability and reliability of the overall production line capacity, the production line runs reasonably smooth, for the customer to establish a high standard of green mining demonstrative projects.

Raw material:magnetite

Capacity:1000T/H

Discharge size:0-25mm

Equipment Configuration:Two sets of feeders F5X1660, two sets of C6X1450×1100 jaw crushers, one set of HST450(S) single-cylinder hydraulic cone crusher, four sets of HPT300M hydraulic cone crushers, one set of S5X3680-3T heavy-duty vibrating screen, two sets of S5X3075-3T heavy-duty vibrating screens.

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

two sets of F5X1660 grizzly feeder

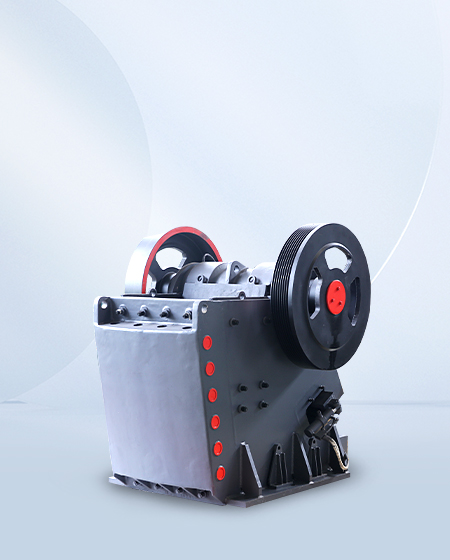

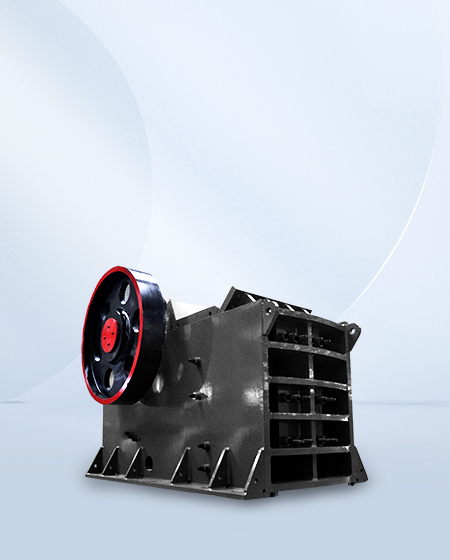

two sets of C5X1450×1100 jaw crushers

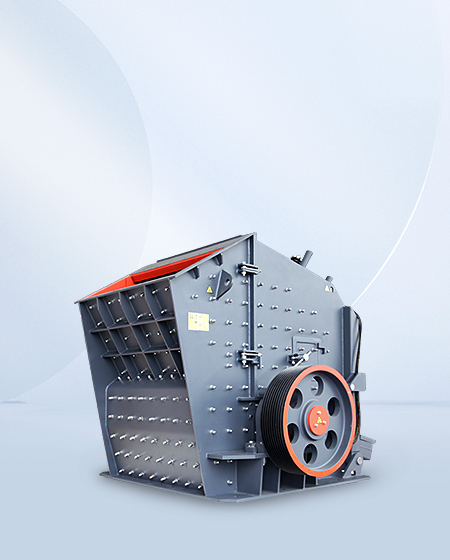

one set of HST450S (coarse cavity type) single-cylinder hydraulic cone crusher

four sets of HPT300 multi-cylinder hydraulic cone crushers

one set of heavy duty vibrating screen S5X3680-3T and two sets of heavy duty vibrating screens S5X3075-3T.

one coarse crushing + two ‘crushing + screening’ closed-circuit system, four sets of fine crushing multi-cylinder cone crusher and two sets of heavy-duty vibrating screen, screening capacity to improve the effect of screening cleaner, the overall equipment utilisation rate is high, and the production stable. Adopting four sets of HPT300 multi-cylinder hydraulic cone crushers, the fine crushing effect is better, the one-time finished product rate is high, the ratio of repeated crushing of returned materials is reduced, the abrasion of the cone crusher is reduced, the wear and tear of the vibrating screen is lowered, and the stability of the production capacity is guaranteed. Big model of vibrating screens reduce the number of equipment models, belt conveyor quantity and floor area, thus less spare part types are needed and maintenance costs are low.

Metal ore consumes a lot of raw materials, electricity and steel in the process of crushing. Our HPT multi-cylinder hydraulic cone crusher adopts the principle of ‘laminar crushing’, making full use of the interactions between materials for crushing, achieving ‘more crushing and less grinding’, which greatly lowers the production cost of enterprises, and is a representative of energy-saving and energy-consuming equipment. It is a representative energy-saving and consumption-reducing equipment. The HPT is equipped with medium and fine crushing cavities to meet the demands of the process. In the metal ore crushing (three sections and one closed circuit) process, as a medium crushing equipment, the finished product content of the crushed material is high, reducing the load on the fine crushing equipment; as a fine crushing equipment, the finished product rate is high, the circulation volume is small, the content of fine-grained grade is high, reducing the overall particle size of the product into the mill. In the field of metal mines, our HPT Multi-cylinder hydraulic cone crusher is widely used in the gold, copper, iron, manganese, nickel, lead-zinc ore aluminium ore, magnesium ore and other metal mines. With the advantages of high production efficiency and high quality material, it is favoured by state-owned enterprises, central enterprises and large private enterprises. It is commonly applied in many metal mine projects.