Photo Album

Working Principle

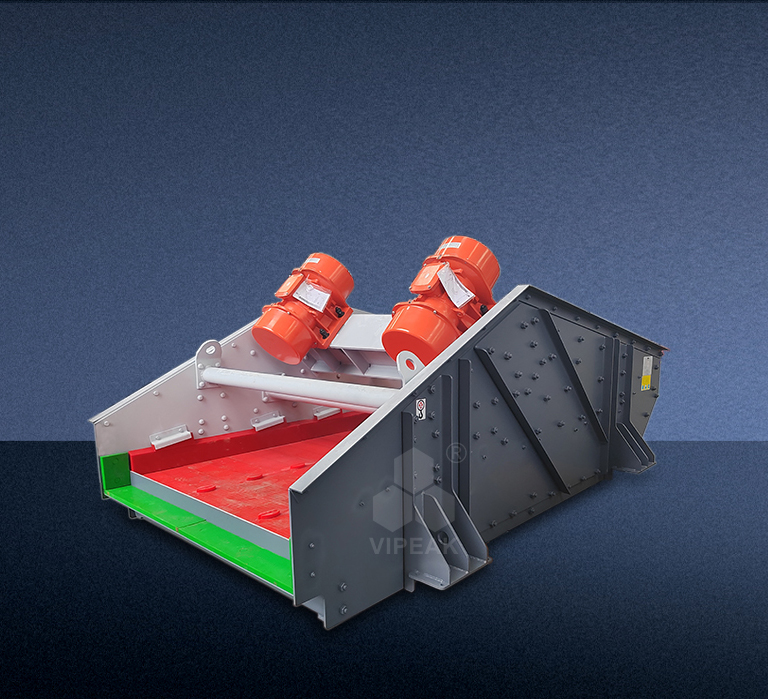

The SL Linear Vibrating Screen mainly consists of a screen box, vibration motor or exciter, rubber springs, support base, and drive assembly.

It is driven by dual vibration motors or dual-shaft exciters (featuring four SV exciters or side-mounted motors) that rotate in opposite directions to achieve self-synchronous vibration.

During operation, the rotating eccentric blocks generate a rated exciting force, causing the screen body to vibrate linearly. Materials are projected and move forward in a straight path across the screen surface.

Thanks to its high-frequency (1000–1500 rpm), low-amplitude motion, the SL screen delivers exceptional efficiency in dewatering, desliming, and fine particle classification.

Performance

High Vibration Intensity, Large Processing Capacity

Vibration intensity (G-force) is a key indicator of screening performance — higher intensity means greater throughput.The SL Series is designed according to international leading standards, featuring an advanced beam frame or large crossbeam structure. The maximum vibration intensity reaches 4.8G (for models with the “H” suffix), achieving over 20% higher performance compared with traditional linear screens.

Rubber Spring Support & Weld-Free Side Plates

Compared with conventional metal springs, rubber springs offer greater load-bearing capacity, longer service life, smoother operation, lower noise, and minimal impact on the foundation.All structural connections between the screen box and side plates use high-strength torsion-shear bolts for steel structures (tensile strength 900 MPa) — three times stronger than riveted joints (300 MPa). This ensures firm fastening and easier replacement.No welding points are present on the side plates, effectively eliminating welding stress and preventing cracking.

Industry-Leading High Configuration

Models with the “H” suffix are equipped with SV modular exciters (same configuration as the S5X vibrating screen) and customized P5-grade bearings designed for heavy-duty vibration.Other models adopt Italian OLI-Wolong brand vibration motors with premium NSK/FAG/SKF bearings.All models come standard with modular polyurethane screen panels, polyurethane discharge liners, and polyurethane side guards, ensuring long service life and easy replacement.

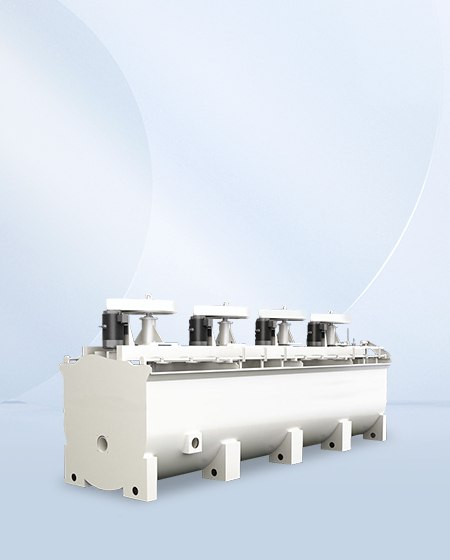

SV Modular Exciter — Powerful and Convenient

The SV modular exciter system is available in SVI–SV4 configurations. By adjusting the number of counterweights, it can meet various vibration force requirements for different screen sizes.The exciter features high interchangeability, standardization, and modularity, with a fully detachable design, longer bearing life, greater vibration strength, and easy amplitude adjustment.Its grease lubrication system ensures simple, clean, and reliable operation.

Specifications - Technical Data

Related Cases

-

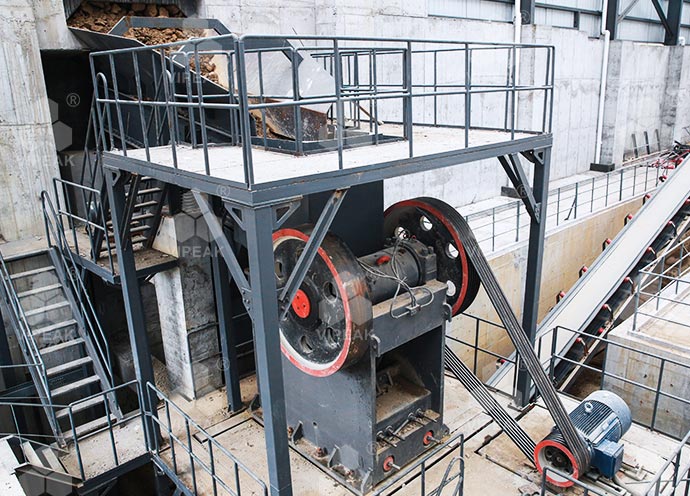

Malaysia Stone & Sand Production Site

-

Guizhou Copper Ore Crushing Line Project

-

Iron Ore Crushing Plant Solution Design