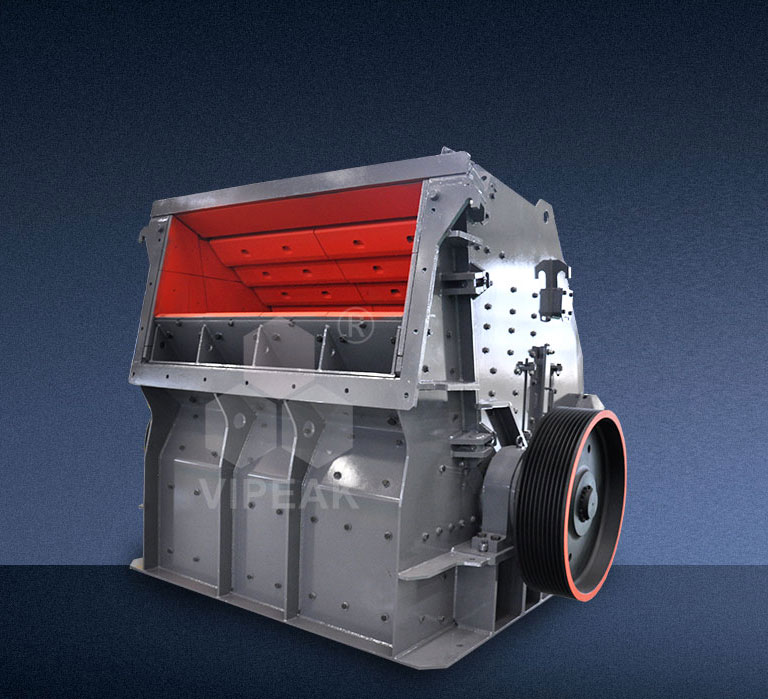

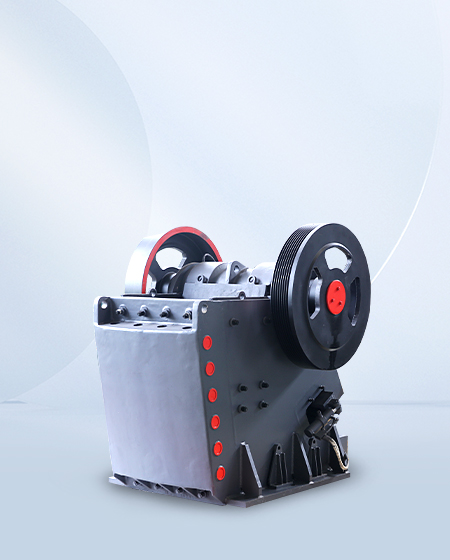

Photo Album

Working Principle

CI5X Series Impact Crusher crushes material by striking energy.when it works,the motor drives the rotor rotate at a high speed,on which the blow bar is installed .as soon as the material get into the affecting area of the blow bar,they will be stroke by the blow bar and be thrown to the impact devices around the rotor.the high speed forces the material to rebound from the impact liner to the area where the blow bar effects until they have been crushed to the required size.the clearance between the impact rack and the rotor can be adjusted to change the size and shape of the end product.

Performance

Integrated Application Of Latest Scientific Research Achievements

Based on the analysis of technical details and operating conditions of a good many domestic and foreign impact crushers, CI5X Impact Crushers integrated many latest scientific research achievements, for example, those concerning crushing chamber, rotor and adjusting device. Thus, the crushing operation and maintenance reach higher level.

Higher Crushing Efficiency – Heavy-duty Rotor with Strong Rotary Inertia and High Precision

CI5X Impact Crusher adopts the heavy-duty rotor with strong rotary inertia and high precision. Meanwhile, it is equipped with high-quality bearings, ensuring the precision and big holding capability of the rotor. So, further, materials can be fully crushed. The crushing ratio is bigger.

multifunctional hydraulic operational system improving working efficiency

Multifunctional Hydraulic Operational System Improving Working Efficiency

CI5X Impact Crusher uses multifunctional hydraulic operational system which boasts high adjustment precision and high velocity. Meanwhile, the replacement and maintenance of hammer and impact blocks and the adjustment of discharging granularity get easier, which further cuts costs on labor and time.involute crushing chamber ensuring shape of finished products

Involute Crushing Chamber Ensuring Shape of Finished Products

The involute crushing chamber of CI5X Impact Crusher is efficient. Materials can be crushed several times inside the chamber. After crushing, finished products have good cubic shape which can better serve as high-quality aggregates.Digitalized Processing, Higher Precision

There are tens of lines of numerical controlling machine tools. Operations such as steel plates' cutting, bending, planing, milling and paint spraying are all controlled numerically. The machining precision is high, especially for the core parts.

Specifications - Technical Data

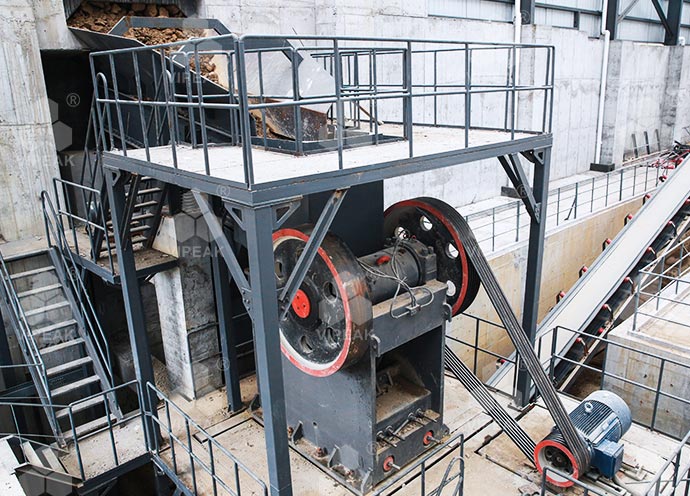

Related Cases

-

Malaysia Stone & Sand Production Site

-

Guizhou Copper Ore Crushing Line Project

-

Iron Ore Crushing Plant Solution Design