Raw materials are unloaded into the hopper by tipper trucks, fed by vibrating feeder, after pre-screening larger 120mm enter the jaw crusher for primary crushing, and after coarse crushing, the materials enter the transfer bin for buffering, and then conveyed by belt conveyor to medium and fine crushing workshop for crushing evenly.

After crushing, the crushed materials are conveyed to the vibrating screen for screening, and the large materials on the screen are returned to the fine crushing single-cylinder cone crusher through the belt conveyor to form a closed-circuit crushing and screening cycle.

Material:Granite

Finished Product:Aggregate

Usage:Highway and railway construction

Input size:900mm

Output size:0-5-10-31.5mm

Capacity:1100TPH

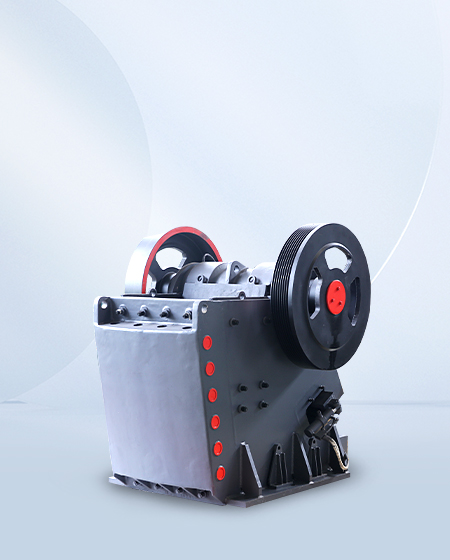

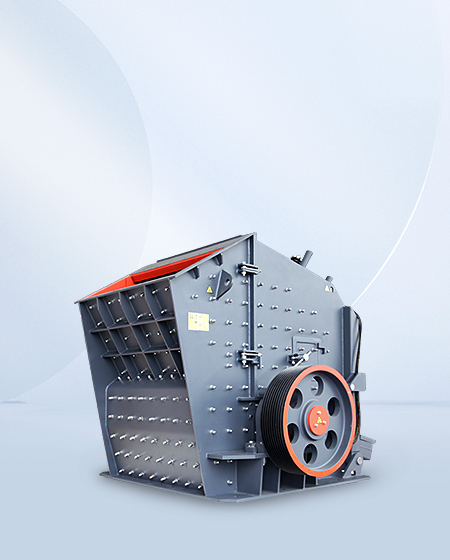

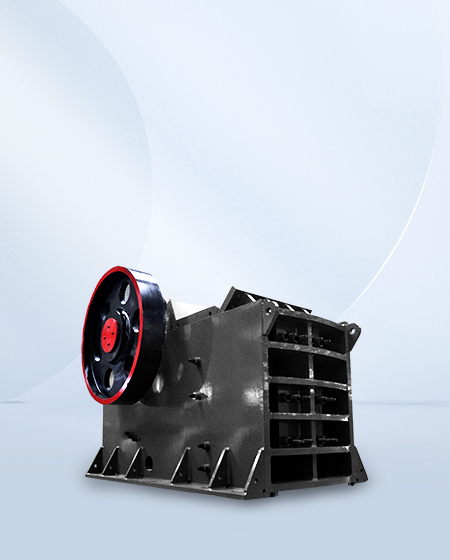

Main equipments:Vibrrating feeder, Jaw crusher, HST cone crusher, vertical shaft impact crusher,vibrating screen.

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

In order to ensure the quality of sand, the screen mesh has been specially designed, after shaping the material after screening into the finished product warehouse directly loading trucks.

A full range of reliability design to ensure a low failure rate and long-term stability of the product use requirements

The introduction of ergonomic design theory makes the replacement of wearing parts and machine maintenance easier and more convenient, reduces downtime and lowers operating costs.

Fully enclosed plant design, professional dust removal equipment, advanced sewage treatment system and intelligent control system, etc., fully guarantee the quality of aggregates, green environmental protection and recycling synergistic development.

The high-quality aggregate produced by this production line serves the local new highway, railway and other infrastructure projects, contributing to the local economic development. The equipment has been running stably since it was put into operation, and the designed output meets the customer's requirements, solving the local demand for sand and gravel aggregates. VIPEAK insists on innovation, strives for excellence in product quality, and reaches a win-win situation with customers, which is highly recognised and praised by customers.