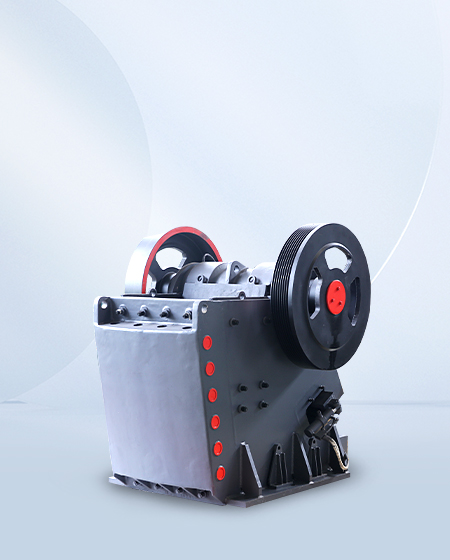

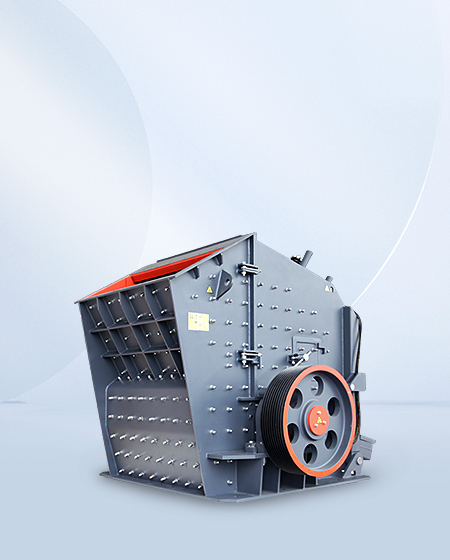

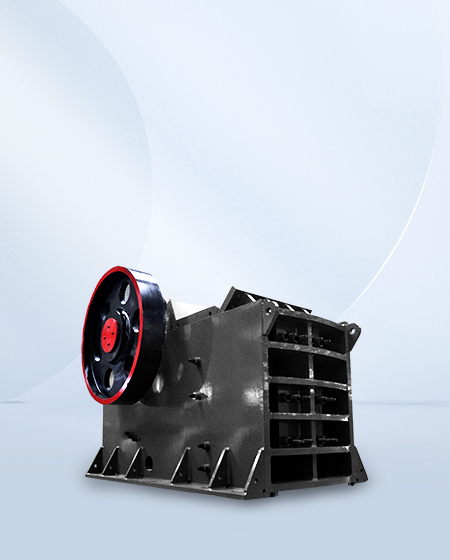

Raw materials are unloaded into the hooper by tipper trucks for pre-screening, and the screened natural sand is sent to the natural sand workshop for storage, and the materials larger than 150mm enter into the jaw crusher for coarse crushing, and after coarse crushing, the materials enter into the medium and fine crushing bin to be crushed by the single-cylinder hydraulic cone crusher, and after screening, the screened materials larger than 31.5mm are fed back to the multi-cylinder hydraulic cone crusher to form a cycle of crushing and screening system. The 5-31.5mm materials screened out after medium and fine crushing are fed evenly by the belt conveyor to the impact crusher for shaping and sand making.

Material:riverstone

Finishe Product:Aggregate, high quality sand

Usage:Providing quality sand and gravel aggregates to local commercial mix enterprises

Input size:500mm

Output size:0-5-10-31.5mm

Capacity:500TPH

Main Equipments:Vibrating feeder, PEW jaw crusher, HST cone crusher, HPT cone crusher, Vertical shaft impact crusher, Vibrating screen.

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

The production line is built according to the river, which reduces the transport cost and shortens the transit distance. It saves a lot of money and time for customers' preliminary investment and later production.

The core parts of the equipment adopt international famous brands, and the precisely matched power of the driving motor can control the cost per unit of product in the optimal state

Wet sand in the production process and the wastewater produced in each link is unified into the filter press workshop, and the wastewater is recycled after unified treatment, so as to save resources and enhance efficiency.

The successful commissioning of the project not only effectively improves the local water environment and achieves the established ecological benefit target, but also provides high-quality sand and gravel aggregate for local infrastructure construction and commercial mixing enterprises.

The harmonious development of ecology, economy and society has been achieved; in the future, VIPEAK will continue to adhere to the development concept that green water and green mountains are golden silver mountains, and take the systematic and complete nature of the equipment as the core point of the solution; take the trend of social development such as low carbonisation, digitisation and intelligence as the important index for upgrading our technology and quality; and use high-quality, low-cost, high-efficiency and low-energy-consumption products, equipment and process solutions to Achieve customer success.