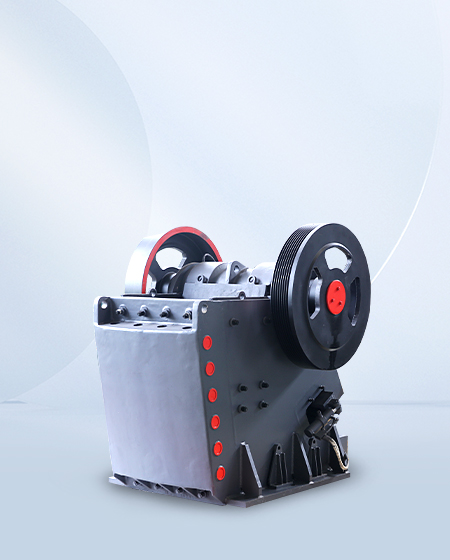

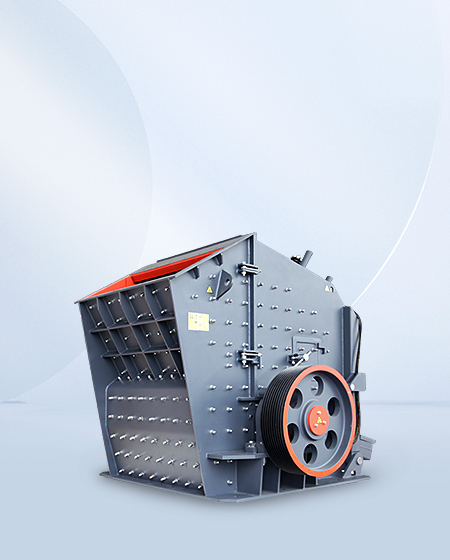

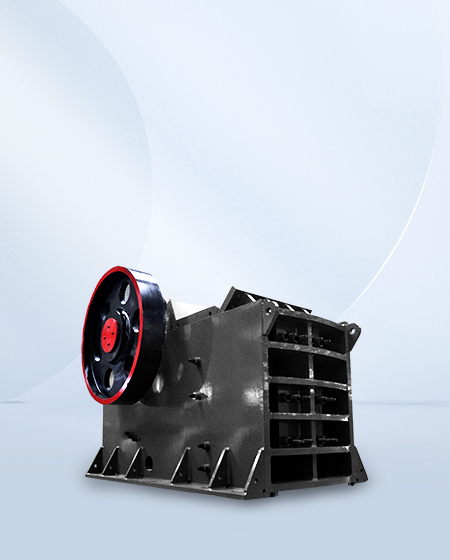

The raw material of this project is limestone, and the equipment configuration is C6X jaw crusher for coarse crushing, 2 sets CI5X impact crusher for medium crushing, 2sets VSI6X vertical shaft impact crusher for shaping sand, and many vibrating screens for sand screening. The company produces a wide range of aggregates, including conventional sand and gravel aggregates for high-speed railway construction and 30-80MM industrial materials for lime kilns.

Material:limestone

Output:Aggregates

Usage:Local infrastructure, high-speed rail construction

Inputsize:950mm

Output size:0-5-10-31.5-80mm

Capacity:1000TPH

Main Equipments:Vibrating feeder, jaw crusher, impact crusher, vertical shaft impact crusher, vibrating screen.

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

VIPEAK has optimised the layout many times to make use of the existing site area which is not sufficient, so as to save the space of the equipment and reduce the investment cost.

A full range of reliability design to ensure a low failure rate and long-term stability of the product use requirements

The introduction of ergonomic design theory makes the replacement of wearing parts and machine maintenance easier and more convenient, reduces downtime and lowers operating costs.

The equipment as a whole adopts advanced dust removal process, reducing dust and noise pollution, environmental protection conditions up to standard, in line with the requirements of green mines

The production line has been running stably and producing efficiently since it was put into operation, and the designed output meets the requirements of customers. It has solved the local demand for sand and gravel aggregate and industrial quicklime, and helped the construction of the local high-speed railway project. This project has also brought considerable economic benefits for the customer, and has been highly praised by the customer.