The owner of the project is an old customer of our group, and it is because of the full recognition of our group's product quality, service and industry influence that we are entrusted with this big project. In line with the ‘green mine’ philosophy, to ‘produce high-quality aggregates’ for building ‘five types of mines’ construction concept, that is, culture-led, the same responsibility and first-class talent ‘Learning’ mine, innovation, green intelligence, science and technology, first-class “intelligent” mine, brand leading, cost reduction and efficiency, first-class management, “quality” mine, clean leading, honest and trustworthy, first-class efficiency. The ‘clean’ mine with honesty, trustworthiness and first-class efficiency, and the ‘pioneer’ mine with Communist Party building, harmony and first-class service.

Adopting mature and reliable processes and equipment in recent years, the whole production process combines dry and wet methods, and the finished products are shaped to produce high-quality aggregates.

Our group adheres to the concept of environmental protection and sustainable development, and adopts the industry's high standard design and construction programme. Our EPC project team is deeply involved in the management of the whole project construction process, and strictly implements the scientific initiative of mining and recovering at the same time, and the whole production line meets the requirements of modular, industrialised, park-based, intelligent and green production.

Project Capacity:1500TPH

Processed Material:Tuff

Raw Material Source:Blasting Raw Material

Raw material size:0-1000mm

Finished product size0-4-6-12-20-26-31.5mm

Processing Technology:Dry

Finished products application:Asphalt water stabilisation station, commercial concrete station, etc., infrastructure high speed, high speed rail, bridges

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

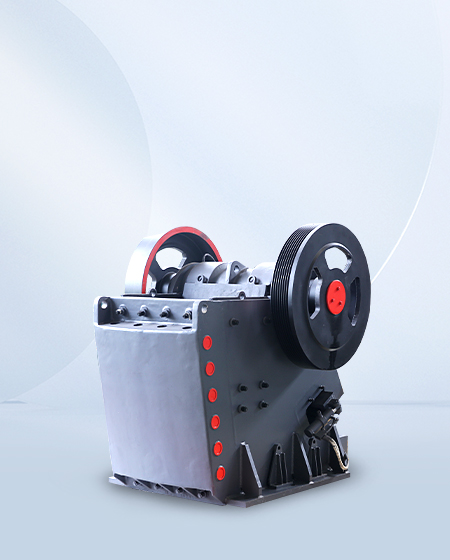

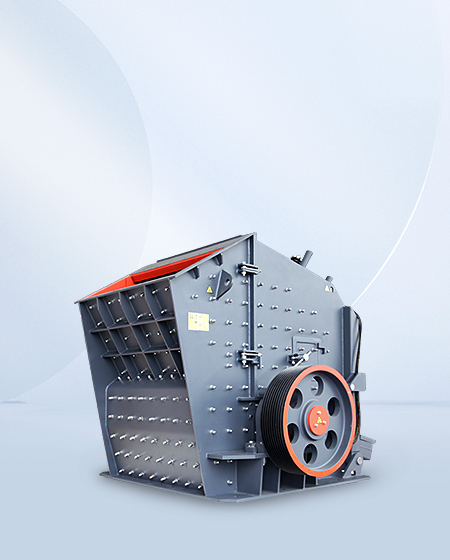

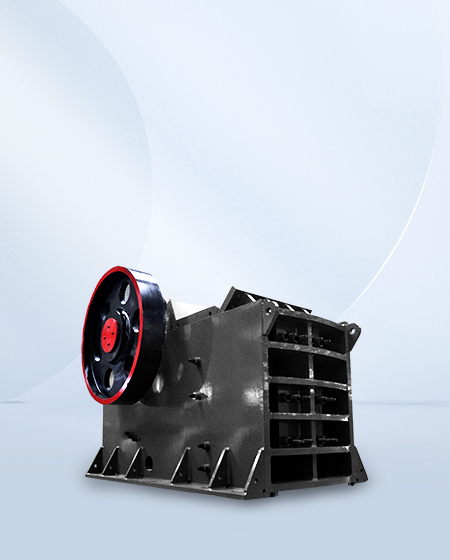

Equipment configuration: 2 sets of F5X1660 feeders, 2 sets of PE1200*1500 jaw crushers, 2 sets of HST315S single-cylinder hydraulic cone crushers, 4 sets of HST315H multi-cylinder hydraulic cone crushers, 3 sets of VSI6X263 vertical shaft impact crushers, 13 sets of vibrating screen of S5X3075-3T and S5X3072, supporting dust collector, powder separator, automated loading system. etc.

The company selects first-class equipment and adopts the classic process of ‘three-stage crushing + one-stage sand shaping’. The coarse crushing process is equipped with a high-efficiency deep-cavity PE1200*1500 jaw crusher, while the medium and fine crushing process adopts the HST315S coarse single-cylinder hydraulic cone crusher with high crushing efficiency and good product shape and the HST315H fine hydraulic cone crusher with dual-purpose VSI6X series vertical shaft impact crusher, and the sand shaping process adopts the VSI6X series vertical shaft impact crusher. The HST315S coarse and HST315H fine hydraulic cone crusher are adopted in the medium and fine crushing process, while the VSI6X series of vertical shaft impact crusher is adopted in the shaping sand making process. More than 20 sets of main and auxiliary equipments together form this production line. After multi-stage crushing and layer by layer screening, the raw ore is not only processed into various specifications of crushed stone, but also transformed into high-value-added high-quality sand and gravel under the shaping effect of the shaping sand making machine, which can satisfy the different needs of high-end and middle-end projects.

Since its commissioning, this production line with a capacity of 1,500 tonnes per hour has not only provided solid resource support for local key projects, but also opened up a new path for the construction of a modernised green and intelligent mine in the region, which will help the Central Plains to create a new model of high-end manufacturing, ecological and environmental protection, green balance and harmonious development.

From site survey to planning and design, from installation and commissioning to production and efficiency, our company always puts the interests of customers in the first place, professional and rigorous throughout, and ultimately also harvested the old customers of our group of companies and praised!