Recommended MK set mobile all-in-one solution, small footprint, intelligent equipment, short installation period, low investment, this project will process granite, building materials into concrete aggregates.

Raw material:granite

Capacity:200T/H

Input size:≤600mm

Final product size ranges:0-5、5-10、10-20、20-31.5mm

Final product application:concrete aggregates

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

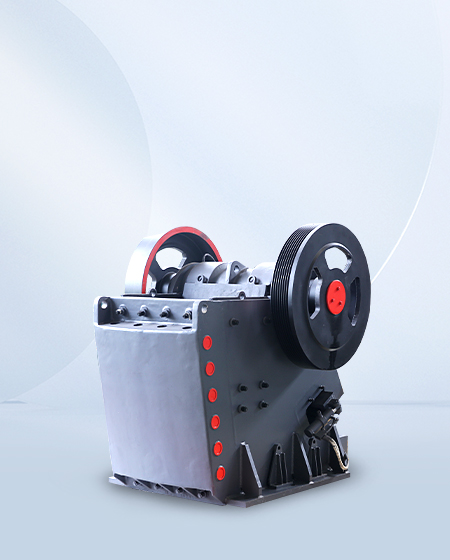

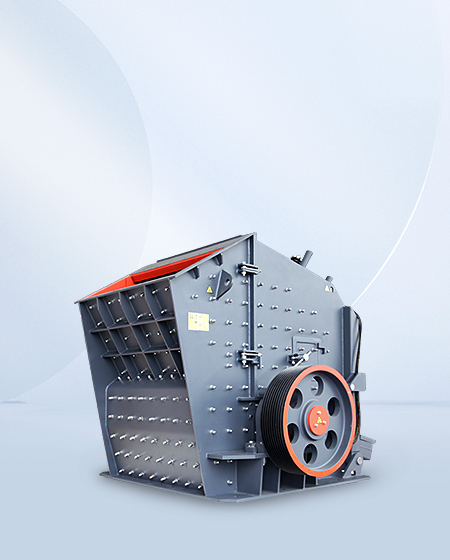

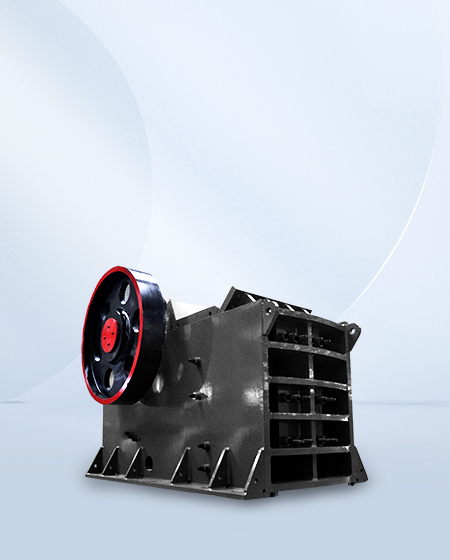

One set of MK75J (GF1245 with PE750*1020 jaw crusher), one set of MK300HS (multi-cylinder Cone Crusher HPT300 with 1536 pre-screening), and one set of MK300S Screening Vehicle (vibrating screening S5X2160-3 with belt conveyor) with on-board belt conveyor and other auxiliary equipments.

1. Solve the pain points of traditional fixed production line with high cost of concrete foundation, long production cycle, slow production, one-time investment and difficult to change the site;

2. Solve the pain point of long installation time and difficult installation of traditional production line;

3. Solve the pain point that the traditional production line covers a large area and affects the stacking space;

4. Solve the pain point of transport difficulty and equipment dispersion affecting the progress;

5. Solve the pain point of complicated operation and difficult maintenance on site;

6. Solve the pain point of using many maintenance points and consuming a lot.

7. Solve the pain point of high height of coarse crushing and feeding, high number of transit bins and belt conveyors used, and the cost of construction costs.

When visiting the site, the person in charge of the project said, ‘Your group has a perfect service system and professional technical support, from the preliminary programme design to the later preparation and delivery were completed within the estimated time, and finally also successfully completed the trial delivery work. At present, the production line is running very stably, and we are very satisfied with the production capacity and finished products!’