The raw materials for the project are aluminum ore mined from mines (Al2O3 >62%, Al/Si≥5), and the finished products are aluminum ore blocks below 11mm, which must meet the feeding requirements of the ball mill. The project is located in the production and processing area of Baise Mining Area in Guangxi, providing refined aluminum powder for subsequent processing and production. The finished product output is about 800 tons per hour, making it a key aluminum ore crushing project in the local area, bringing rich economic benefits to customers and the local area.

Raw material:Aluminum Ore

Finished product:Aluminum Ore Blocks

Final application:Aluminum ore deep processing

Input size:800mm

Output size range:0-11mm

Capacity:800tph

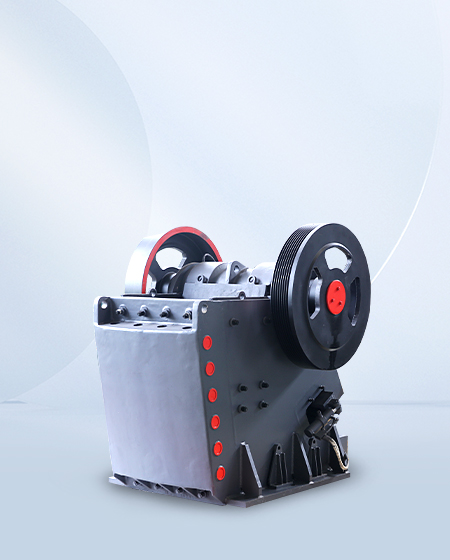

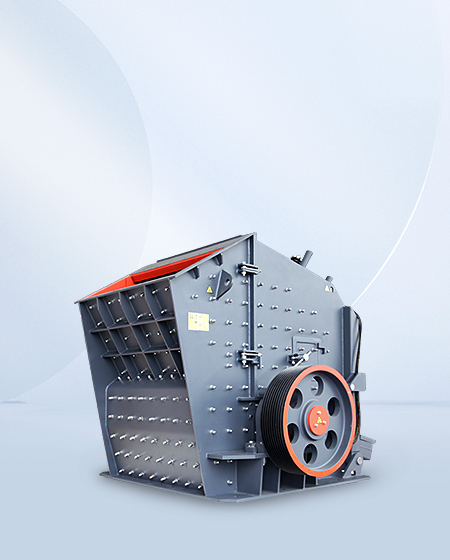

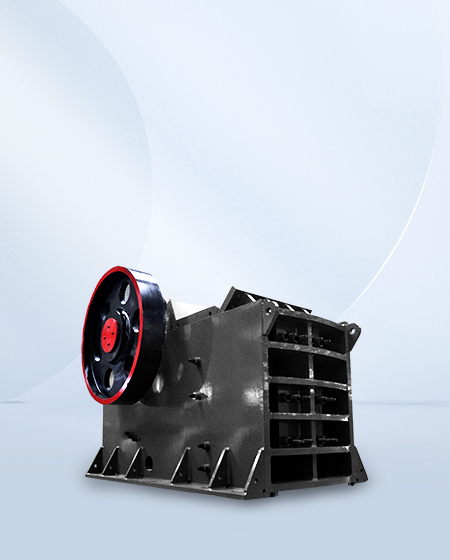

Equipments:F5X1660 Vibrating feeder,C6X145 Cylinder Hydraulic Jaw Crusher,HST315 Single Cylinder Hydraulic Cone Crusher, HPT 500 High Performance Hydraulic Cone Crusher,S5X3075-3T Vubrating Screen.

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

The company adopts the industry's cutting-edge crushing technology and equipment, with efficient crushing capacity and precise crushing particle size control, ensuring that aluminum ore can be crushed quickly and with high quality. The application of these advanced technologies not only improves production efficiency, but also provides a strong guarantee for product quality

The overall design of the production line is very reasonable, the layout between various equipment is compact and scientific, the material conveying path is smooth, and unnecessary transfer links and distances are reduced. This not only improves production efficiency, but also reduces material losses and potential risks during the transportation process.

All major equipment has demonstrated high stability and durability during long-term operation. Whether facing routine production tasks or under different working conditions, it can maintain a stable operating state, and all parameter indicators are maintained within a reasonable range.

During the design and operation of the equipment, some energy-saving technologies and measures were adopted to reduce energy consumption to a certain extent. At the same time, the emission control of pollutants such as dust was also relatively effective, reducing the negative impact on the environment.

The crushing production line has shown very reliable performance and provided a good material basis for subsequent processing procedures. With high production efficiency and stable equipment operation, the production line can meet the expected production schedule requirements, ensuring a stable supply of aluminum ore and gaining unanimous praise from customers.