The project is located in Linfen, Shanxi, with a designed capacity of 500tph. The processed material is raw iron ore mined in caves. The feed size is less than 700mm. The finished product fineness is less than 11mm after crushing. The material enters the grinding equipment for grinding. After the magnetic separation reaches a certain standard, it is sent to the steel plant for processing. The project uses a full set of crushing equipment fromVipeak Mining Machinery, which has been running stably since it was put into working.

Material:iron ore

Finished product:iron ore blocks

Final application:Steel plant deep processing

Input size:700mm

Output size:0-11mm

Capacity:500T

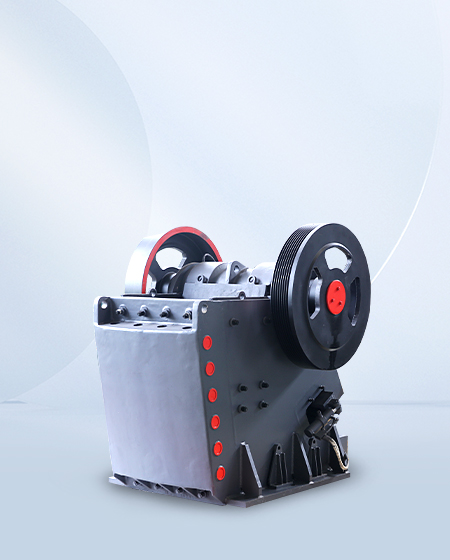

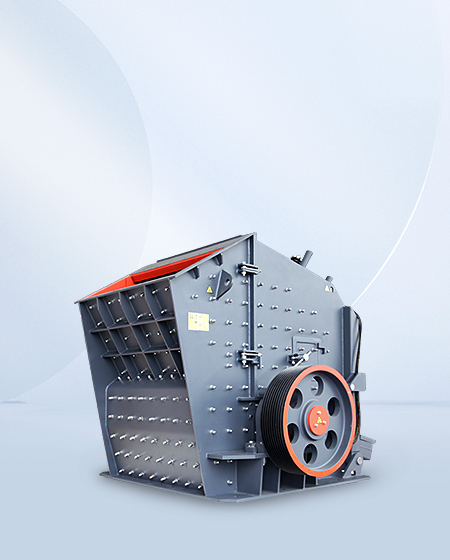

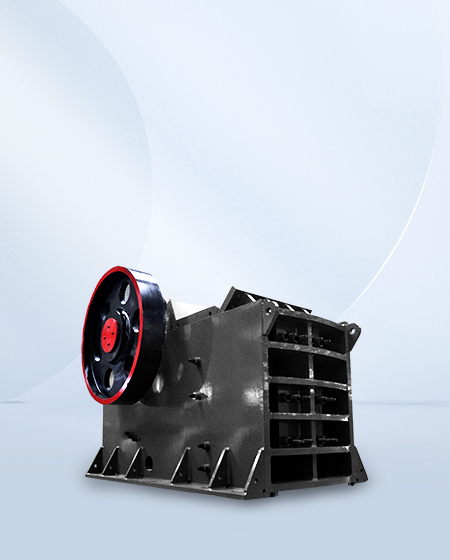

Equipments:F5X1345 Vibrating Feeder, C6X125 Europen Cylinder Hydraulic Jaw crusher, HST250 Single Cylinder Hydraulic Cone Crusher, HST315 Single Cylinder Hydraulic Cone Crusher, S5X3072-2Vibrating screen

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

Capacity: more

The fully automatic control system provides a variety of operating modes for users to choose, can continuously monitor the actual load inside the equipment, and display various operating parameters in real time.

The compact layout not only saves area, but also makes inspection and maintenance very convenient, avoiding economic losses caused by inconvenient maintenance. It also makes operation and maintenance more convenient, and workers can quickly reach various key parts for operation.

The screens are placed in parallel, and the finished products are transported by the same belt conveyor. Customers can adjust the output material ratio according to market conditions, and the capacity can achieve the expected economic and social benefits.

ll equipment works in a fully enclosed environment and is equipped with special dust removal devices, fully meeting national environmental protection standards and achieving an effective combination of economic and environmental benefits.

Since the production line was put into operation, the overall performance has been relatively stable. In terms of equipment, key equipment etc have good performance and can continuously and effectively complete the iron ore crushing task, ensuring the continuity of production. In terms of production efficiency, the expected goal has been achieved, and the crushed iron ore can be output on time and in quantity, meeting the needs of subsequent processes.