Photo Album

Working Principle

A B6X Belt Conveyor uses a conveying belt to hold and transport materials. The conveying belt winds around the transmission drum and the tension drum to form a loop strap. Its upper and lower part are supported by a carrier roller which can limit the deflection sag of the conveying belt. The tension device provides necessary tension for the normal operation of the conveying belt. During operation, the drive device drives the transmission drum, and then the conveying belt starts working under the friction between the transmission drum and the conveying belt. When the conveying belt is running, materials on the belt can move with it together thereby.

Performance

Safer C-type Steel Having Strong Rigidity

Generally, traditional belt conveyors uses channel steel and carrier roller frame with the rack relatively thin. B6X Belt Conveyor uses C-type steel to replace channel steel and equips side guard board. Based on this improvement, the overall rigidity of B6X Belt Conveyor's rack greatly increases.

More Stable Splay Landing Leg Easier for Installation

Based on the feedback of users and installation engineers, the landing leg of traditional belt conveyors has a series of problems including poor stability, loose bolts and complex installation. Therefore, Vipeak adopts reversed splay landing leg in the design of B6X Belt Conveyor which has excellent stability. The combining use of three-link installation structure increases the stability. The installation procedures are greatly simplified due to the fact that there is no need for fastening with a large number of bolts.

Long-distance Headstock More Beneficial to Material Falling

Benefiting from the super-strong rigidity of B6X Belt Conveyor's rack, the use of long-distance headstock gets possible. Based on this design, the maximum radius of material pile is 1.5~2 times of that of traditional belt conveyors, which is very beneficial to material falling in the process of production and can effectively avoid the loader or other machines from clashing the holder when shoveling materials.

Cycloidal Reducer with Higher Technical Grade

According to users' feedbacks, the electric drum used in traditional belt conveyors isn't suitable for high-power drive and always has trouble of heating which leads the short life expectancy. Sometimes it is difficult to replace the broken parts in the some foreign countries. Therefore, Vipeak adopts the cycloidal reducer with higher technical grade, which greatly enhances stability and is very convenient for maintenance and replacement.

Related Cases

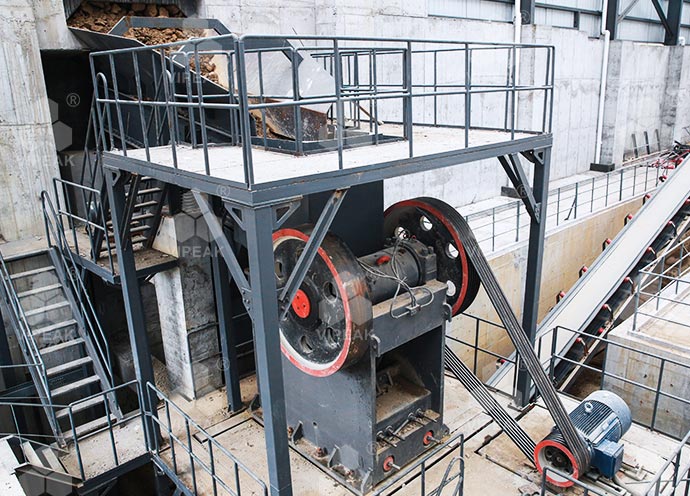

-

Malaysia Stone & Sand Production Site

-

Guizhou Copper Ore Crushing Line Project

-

Iron Ore Crushing Plant Solution Design