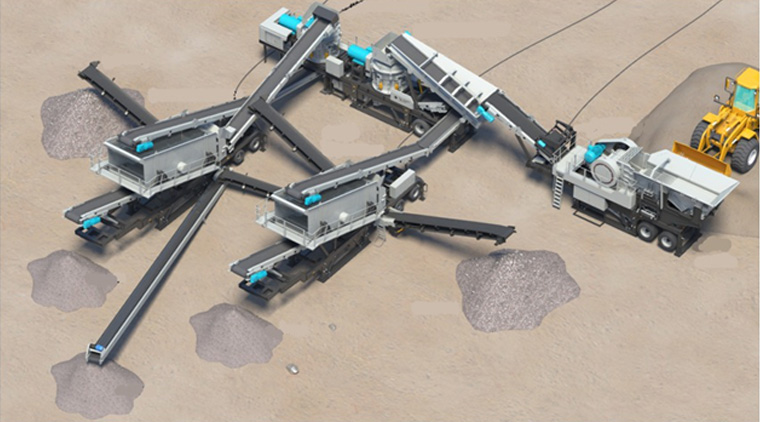

Recently, the mobile crushing plant in Peru customer has been installed and successfully tested, and it has been continuously produced and operated stably.

Due to the impact of COVID-19, the engineer of Vipeak could not handle the visa in time to go to the customer's site to install the equipment. Therefore, under the online guidance of the engineers of Vipeak, the customer's engineers installed and commissioned the mobile plant, and the continuous trial production proved that the equipment was in good operation.

The mobile station adopts a 4-combination structure, means 4 main equipments are assembled on a mobile unit, and the 4 equipments cooperate with a vehicle-mounted belt conveyor to form a crushing production line.

The mobile crushing plant is usually powered by an external power source. The raw materials are uniformly delivered to the jaw crusher by the vibrating feeder for coarse crushing. Next, the coarse crushed materials are delivered to the vibrating screen where materials meeting size requirement would be screened as finished products, the unqualified ones delivered back to cone crusher for secondary crushing, forming a closed circuit and multiple cycles. The granularity of finished products can be decided according to the needs of users.

This customer's requirements as following:

Material: Gold ore

Input size: 0-300mm

Output size: 0-9.5mm

Capacity: 50-100tph

The main equipments of the mobile plant is as follows:

The advantages of the mobile plant as following:

1. Large storage bin, full daily production and energy saving

The coarse crushing equipment has a large feeding bin volume of 6.5M³, widened feeding baffle to 8M³, adjustable feeding speed, large feeding storage capacity. In the 200-300tph project, the feeder is carefully configured with the GF1245 model, with double-layered grizzly bars, and the length reaches 1800MM. It has powerful grate separation and soil removal functions, the medium crushing equipment is equipped with a 4.5M³ transfer feeding hopper with adjustable speed.

It can realize fast and slow uniform feeding, and has a function of intermediate transfer and storage, to ensure continuous and uninterrupted operation, which is more energy-saving.

2. Electric control system

All on-board electronic control system, the electronic control system is equipped with remote start and stop operation terminal interface; After the customer provides the remote low-voltage accessories, it can realize the day and night monitoring operation in the control room under the harsh environment (high temperature exposure, wind and rain, low cold and freezing).

3. Standard hydraulic supports and lifting system

The operation conditions can be realized only by leveling and tamping the road surface at the operation site, no need the concrete foundation. Compared with the hardening of concrete foundation required by the mobile station of others companies, it can greatly reduce the cost of construction, labor and materials, also the installation cost of on-site. The standard gauge of the whole system is equipped with hydraulic support system, which can be delivered, transferred and stored. Without manual handling and connecting the support base, and can be quickly grounded in site and enter operation mode; It also has the function of fast folding and transition.

4. Modular and universal design concept

Modular and universal design concept is adopted in the design of K3 series mobile plant, it can carry out mass production according to the general module, with stable production quality, high precision and short stock cycle.

It is equipped with 100tph and 150tph all-in-one mobile equipment, efficient coarse crushing, medium crushing, screening and full vehicle belt conveyor. have unique environmental protection advantages in terms of small land occupation and dust control capacity, and be more light and flexible.

K3 series mobile crushing plant is a tired-type mobile production line specially designed by Vipeak for small and medium-sized production lines (100-300tph). It is suitable for crushing, screening, shaping and sand making of various soft rocks, hard rocks and construction wastes, such as granite, marble, basalt, limestone, quartz, pebble, iron ore, copper ore, mine waste, construction waste, etc

As the mobile plant is convenient for rapid transfer, rapid assembly and production, which can greatly reduce the installation cost, so the K3 series mobile plant is loved by all customers.

Till now, Vipeak has nearly 100 sets of mobile stations operating in different customers around the world, and continuously creates value for customers.

We expect that this mobile station can continuously create wealth for this customer!

-

Previous:

Dialogue With the World and Pursue Sustainable Development in Aggregates Industry

-

Next:

Don’t Miss Our Special Offer on the Canton Fair 2024