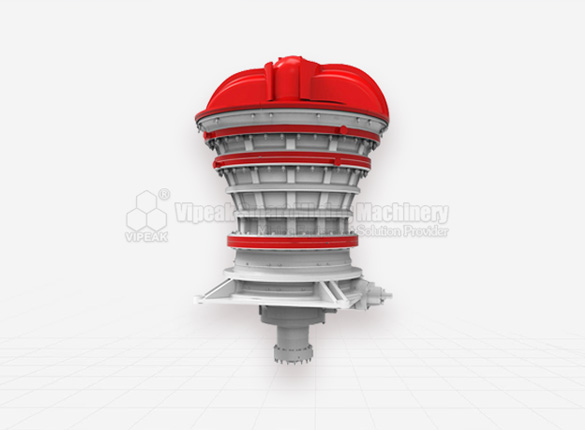

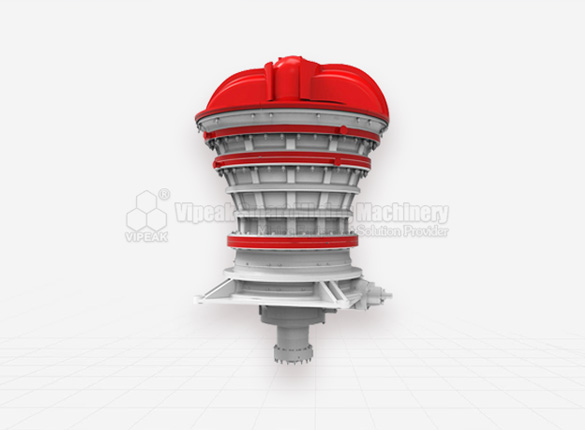

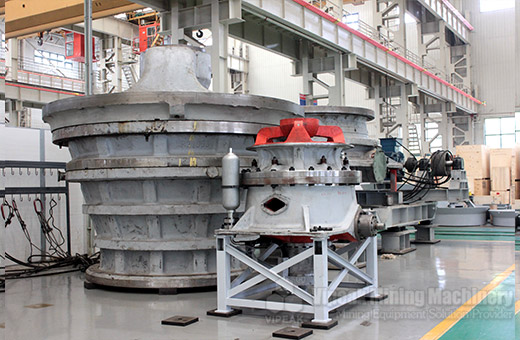

With the super-high crushing capability, super-heavy frame, integral forged main shaft with big diameter and high performance bearings, HGT Gyratory Crusher has longer service life and more stable and safe operation.

Granite, basalt, diabase, limestone, dolomite, iron ore, manganese ore, gold ore, copper ore, etc.

Mining, smelting, building materials, highways, railways, water conservancy and chemical industries and so on.

| Model | Feeding opening(mm) | 最大功率(KW) | 140(mm) | 150(mm) | 165(mm) | 175(mm) | 190(mm) | 200(mm) | 215(mm) | 230(mm) | 240(mm) | 250(mm) |

| HGT4265 | 1065 | 400 | 2015 | 2340 | 2520 | 2875 | - | - | - | - | - | - |

| HGT5065 | 1270 | 400 | - | 2400 | 2785 | 2940 | - | - | - | - | - | - |

| HGT5475 | 1370 | 450 | - | 2890 | 2990 | 3150 | 3340 | 3490 | - | - | - | - |

| HGT6275 | 1575 | 450 | - | 2895 | 3620 | 3820 | 4210 | 4335 | - | - | - | - |

| HGT6089 | 1525 | 630 | - | - | 4200 | 4545 | 5085 | 5300 | 5535 | 5810 | - | - |

| HGT60110 | 1525 | 1250 | - | - | - | 5540 | 6950 | 7340 | 7575 | 8285 | 8600 | 8895 |