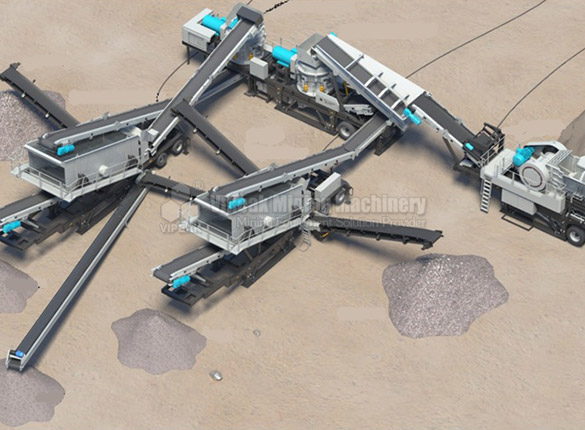

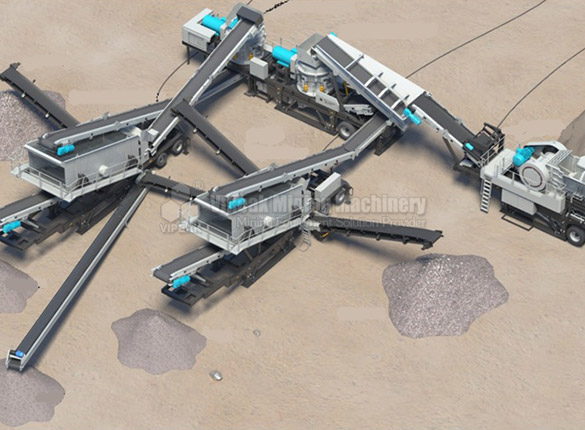

The K3 series are tire-mounted crushing plants specially designed for small and medium-sized production lines (100-300TPH). It is suitable for the crushing, screening, shaping and sand making operations of various soft rock, hard rock, and construction waste. There are a total of 14 models , and 5 chassis frames are equipped to make 19 standard mobile equipment modules in total. K3 series have the following features: mature main equipment, fast assembly to meet operating needs, modular and simple installation, mobile flexibility, standardization and generalization, etc.

Widely applied in coarse, medium and fine crushing, screening, sand making and shaping of metal and non-metallic ore, cement,sand and stone,metallurgy, construction waste treatment and other industries

Working conditions that needs to be moved frequently.

| Mobile Plant Model | Hard & Soft Rock Standard Configurations | |||||||||

| No. |

Stone Feature

(Mobile Crusher)

|

Plant Model | 1:All-in-One Mobile Crushers(4) | 2:Coarse Crushing Mobile Crushers(4) | ||||||

| (All-in-One) Mobile Unit 1 Code | (Coarse Crushing) Mobile Unit 2 Code | |||||||||

| K3T100-4 | K3I100-4 | K3T150-4 | K3E760-1 | K3C100-1 | K3C110-1 | K3CI1213-1C | K3CI1215-1C | |||

| 1 |

Hard Rock (Input≤430mm) |

K3YC-100T | ★ | |||||||

| 2 |

Soft Rock (Input≤430mm) |

K3RC-100T | ★ | |||||||

| 3 |

Hard Rock (Input≤430mm) |

K3YC-150T | ★ | |||||||

| 4 |

Soft Rock (Input≤430mm) |

K3RC-150T | ||||||||

| 5 |

Hard Rock (Input≤530mm) |

K3YC-200T | ① | + | ||||||

| 6 | K3YV-200T | ① | + | |||||||

| 7 |

Soft Rock (Input≤530mm) |

K3RC-200T | ① | + | ||||||

| 8 | K3RV-200T | ① | + | |||||||

| 9 |

Soft Rock Construction Waste (Input≤400mm) |

K3RV-200T | + | |||||||

| 10 |

Hard Rock (Input≤630mm) |

K3YC-300T | + | |||||||

| 11 | K3YC-300T | + | ||||||||

| 12 |

Soft Rock (Input≤630mm) |

K3RC-300T | + | |||||||

| 13 | K3RV-300T | + | ||||||||

| 14 |

Soft Rock Construction Waste (Input≤400mm) |

K3RW-300T | + | |||||||

| Mobile Plant Model | Hard & Soft Rock Standard Configurations | ||||||||||||

| No. |

Stone Feature

(Mobile Crusher)

|

Plant Model | 3:Coarse Crushing Plants(8) | 4:Coarse Crushing Plants(3) | |||||||||

| 3(Medium Crushing One Equipment) Code | 4(Medium Crushing Two Equipment) Code | 5(Screening)Code | |||||||||||

| K3H300-1 | K3CI1213-1 | K3CI1315-1 | K3V9026-1 | K3H300D-2 | K3H300V-2 | K3CI1213V-2 | K3CI1315V-2 | K3S1860-1 | K3S2160-1 | K3S2460-1 | |||

| 1 |

Hard Rock (Input≤430mm) |

K3YC-100T | |||||||||||

| 2 |

Soft Rock (Input≤430mm) |

K3RC-100T | |||||||||||

| 3 |

Hard Rock (Input≤430mm) |

K3YC-150T | |||||||||||

| 4 |

Soft Rock (Input≤430mm) |

K3RC-150T | |||||||||||

| 5 |

Hard Rock (Input≤530mm) |

K3YC-200T | + | + | |||||||||

| 6 | K3YV-200T | + | + | + | |||||||||

| 7 |

Soft Rock (Input≤530mm) |

K3RC-200T | + | + | |||||||||

| 8 | K3RV-200T | + | + | + | |||||||||

| 9 |

Soft Rock Construction Waste (Input≤400mm) |

K3RV-200T | + | ||||||||||

| 10 |

Hard Rock (Input≤630mm) |

K3YC-300T | + | + | + | ||||||||

| 11 | K3YC-300T | + | + | + | + + | ||||||||

| 12 |

Soft Rock (Input≤630mm) |

K3RC-300T | + | + | |||||||||

| 13 | K3RV-300T | + | + + | ||||||||||

| 14 |

Soft Rock Construction Waste (Input≤400mm) |

K3RW-300T | + | ||||||||||

Diverse integrated and fully automatic self-load crushing and screening equipment

Learn More