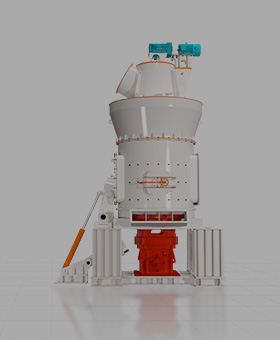

MTW European Type Grinding Mill is new product researched and developed by Vipeak based on ordinary European type grinding mill. Because of more advanced idea and more reliable performance, it has been an intelligent key to the mill market.

Feldspar, calcite, limestone, talc, barite, rare earth, marble, bauxite, phosphate ore, iron oxide red, dolomite, granite, bitumite, anthracite, lignite, kaolin, bentonite, gypsum.

mining industry, chemical engineering, construction material and metallurgy industry over 280 kinds material process

|

Model Specification Name

|

MTW110 | MTW110G | MTW138G | MTW158G | MTW175G | MTW198G | MTW218G |

|

Quantity of roller (PCS) |

4 | 4 | 4 | 4 | 4 | 4 | 4 |

|

Inner diameter of ring (mm) |

Ф1100 | Ф1100 | Ф1380 | Ф1580 | Ф1750 | Ф1980 | Ф2150 |

|

Main Mill Rotating speed (rpm) |

120 | 120 | 100 | 88 | 65-85 | 60-75 | 55-66 |

|

Max. Feeding size(mm) |

25 | 25 | 30 | 30 | 35 | 35 | 40 |

|

Output fineness (Mesh) |

10-325, the finest 400 | ||||||

| Capacity(tph) | 3~10 | 3~10 | 6~20 | 13 | 10~35 | 18 | 20-50 |

|

Dimension (L×W×H)(mm) |

6186×8041×8640 | 6186×8041×8640 | 7262×10010×10010 | 10200x9100x10100 | 10171×10023×9916 | 12500x9500x11400 | 14300x11153x10351 |

| Weight(t) | 15 | 15 | 25.5 | 39 | 47 | 64 | 96 |

| Model |

Main mill (KW) |

Classifier (KW) |

Blower (KW) |

Bucket elevator (KW) |

Jaw crusher/ hammer crusher |

Feeder | ||

| Model |

Power (KW) |

Model |

Power (W) |

|||||

| MTW110 | 55 | 7.5 | 55 | 3 | PE250×400 | 15 | GZ2F | 0.15 |

| MTW110G | 55 | 7.5 | 55 | 3 | PE250×400 | 15 | GZ2F | 0.15 |

| MTW138G | 90 | 18.5 | 110 | 4 | PE250×750 | 22 | GZ3F | 0.2 |

| MTW158G | 132 | 22 | 132 | 4 | PE250×750 | 22 | GZ3F | 0.2 |

| MTW175G | 160 | 30 | 200 | 4 | PE250×750 | 22 | GZ4F | 0.45 |

| MTW198G | 220 | 37 | 250 | 11 | PC1010 | 110 | GZ5F | 0.65 |

| MTW218G | 280 | 55 | 315 | 11 | PC1010 | 110 | GZ5F | 0.65 |